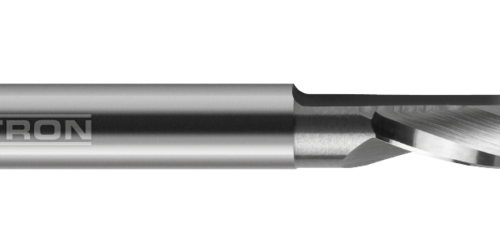

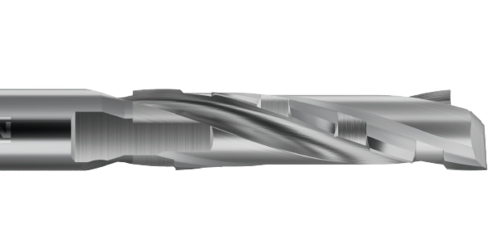

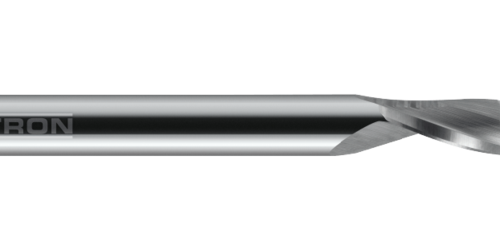

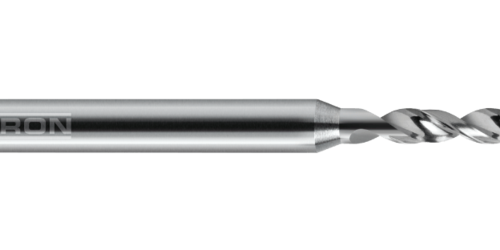

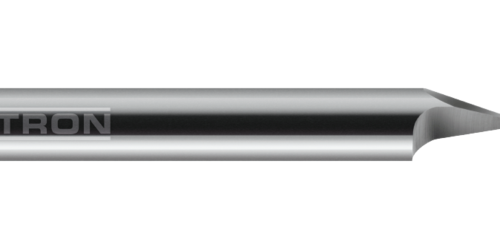

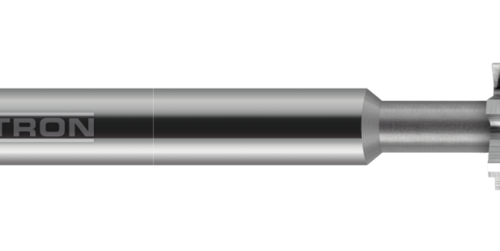

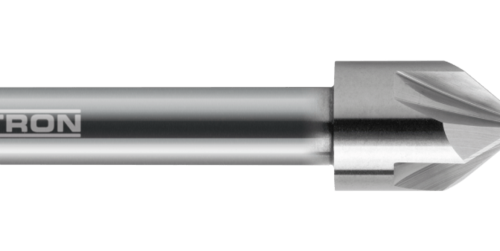

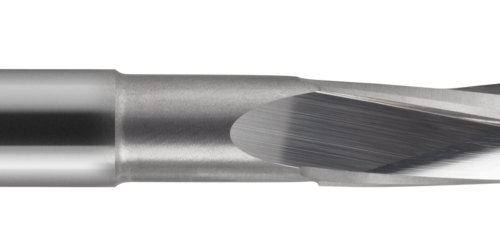

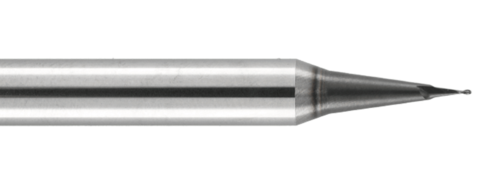

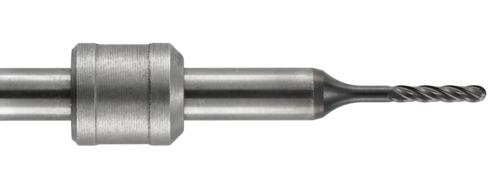

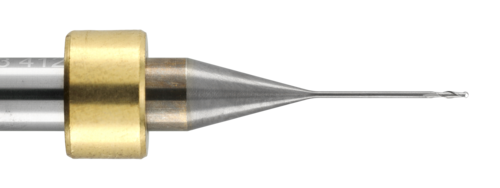

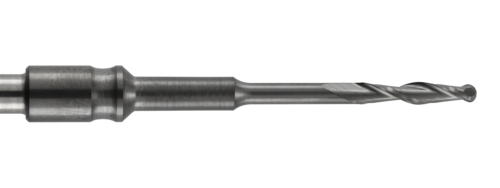

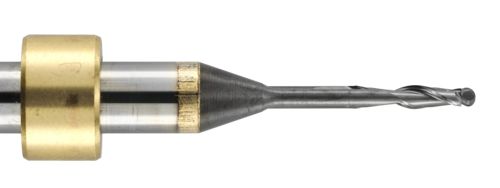

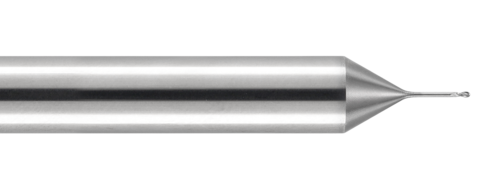

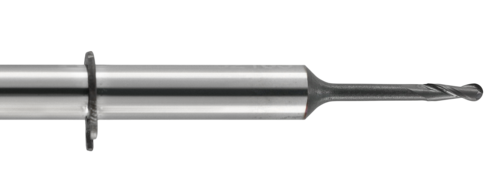

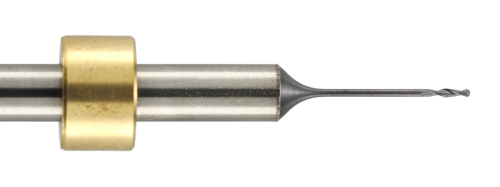

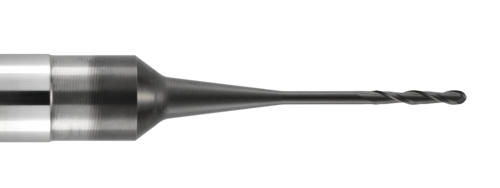

From the product idea to the development and production up to the testing, DATRON bundles all competences around our DATRON high-speed milling tools. Thanks to state-of-the-art production technologies in our own tool grinding shop and the know-how of our DATRON tool experts, we manufacture quickly, flexibly and with a focus on highest precision.

Find the optimal tool solution in our DATRON online store or let our experts from the DATRON Competence Center Tools advise you on individual special tools.

Datron

High-Speed Milling Tools

Discover our DATRON Online Shop

Note: Our shop is only for German customers

DATRON SHOP

Or reach us at:

Regrinding service

New bite for your "old ones" - the DATRON regrinding service

- Contact us if you have tools for regrinding

- You receive a DATRON box from us tailored to your requirements

- You pack your tools according to instructions and register a free pick-up order

- We check your tools for economic efficiency of the desired reconditioning

- After completion, your tools will be returned immediately in original quality, checked and documented.

Contact

Please feel free to contact us at any time!

If you have any questions or would like to know more about our products, please do not hesitate to contact us. We are happy to help!