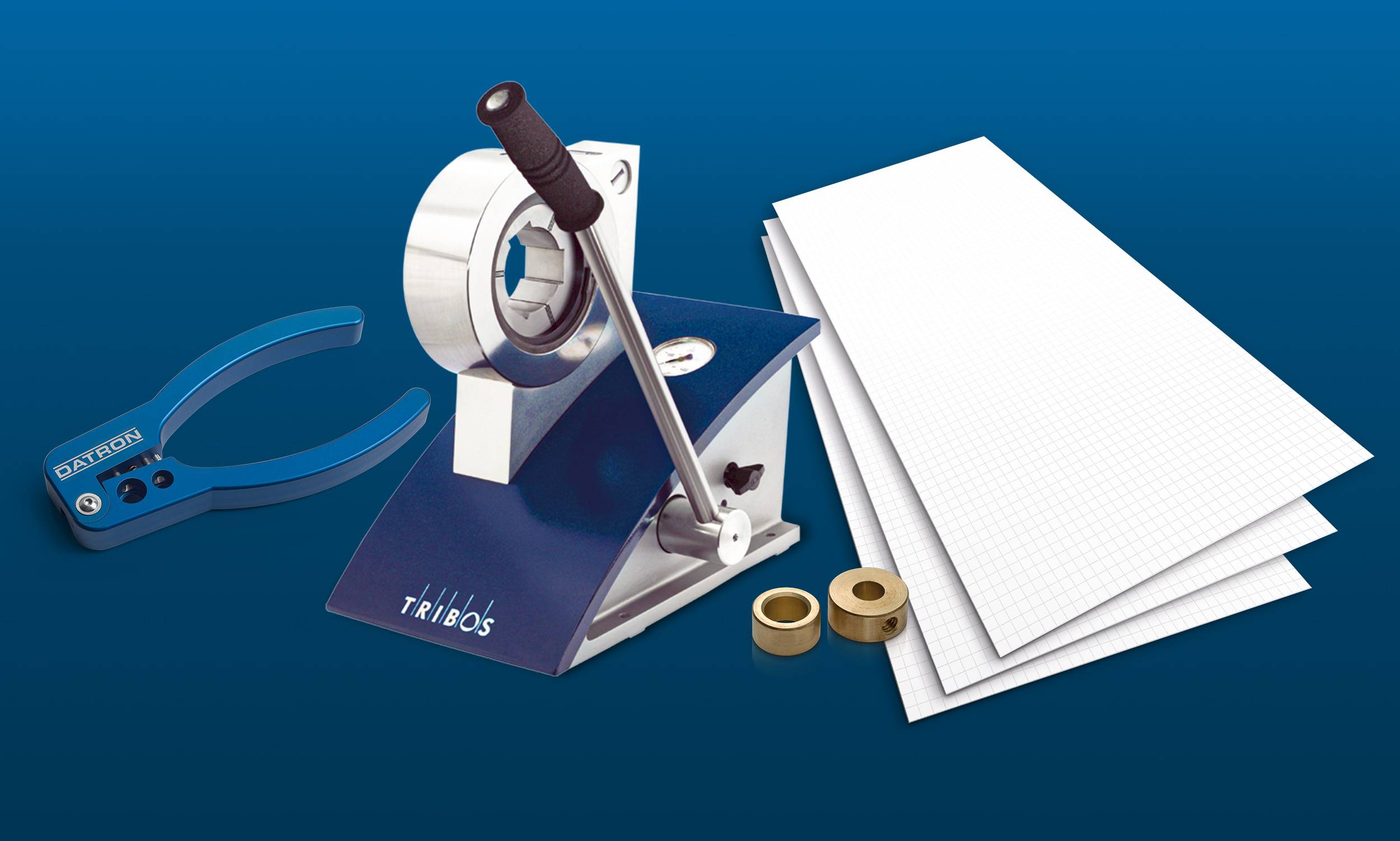

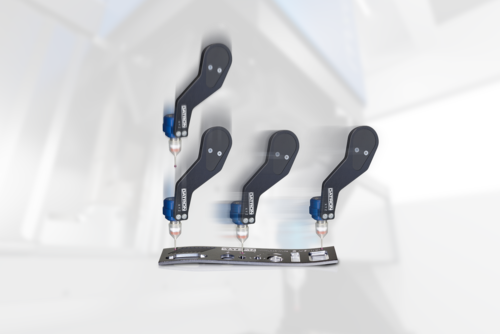

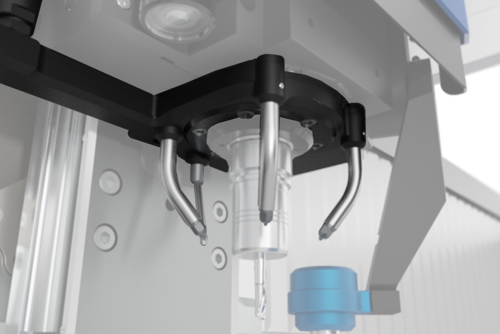

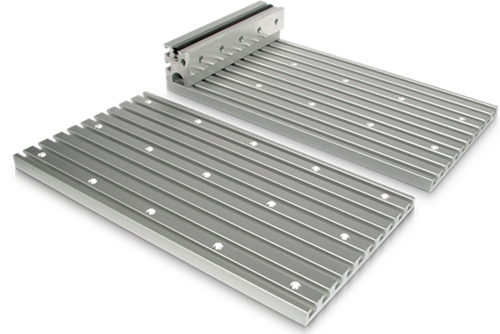

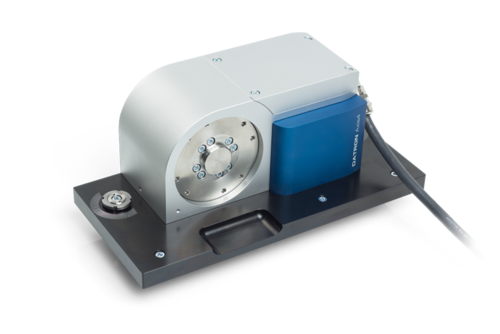

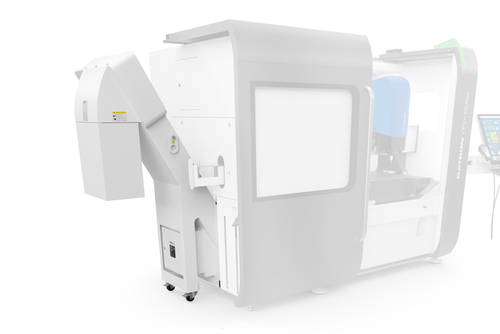

The efficiency of CNC production is decisively determined by the accessories. That is why DATRON develops high-performance accessories for effective and therefore profitable work. These are designed to increase the performance and efficiency of the entire production process, enabling companies to become more competitive. From tool changers and clamping technology to measuring systems, DATRON offers targeted CNC accessories that aim to make manufacturing and production more efficient, cost-effective and of higher quality.

Dirk Iller

Please feel free to contact me at any time!

If you have any questions or need more information about our CNC accessories or our machines, please do not hesitate to contact me.