Sensor XYZ

Simply swivel into the workspace and increase the manufacturing quality in seconds or simply check the dimensional accuracy: With the DATRON 3D sensor we navigate you quickly, easily and comfortably over all imponderables.

Three-dimensional touch sensor

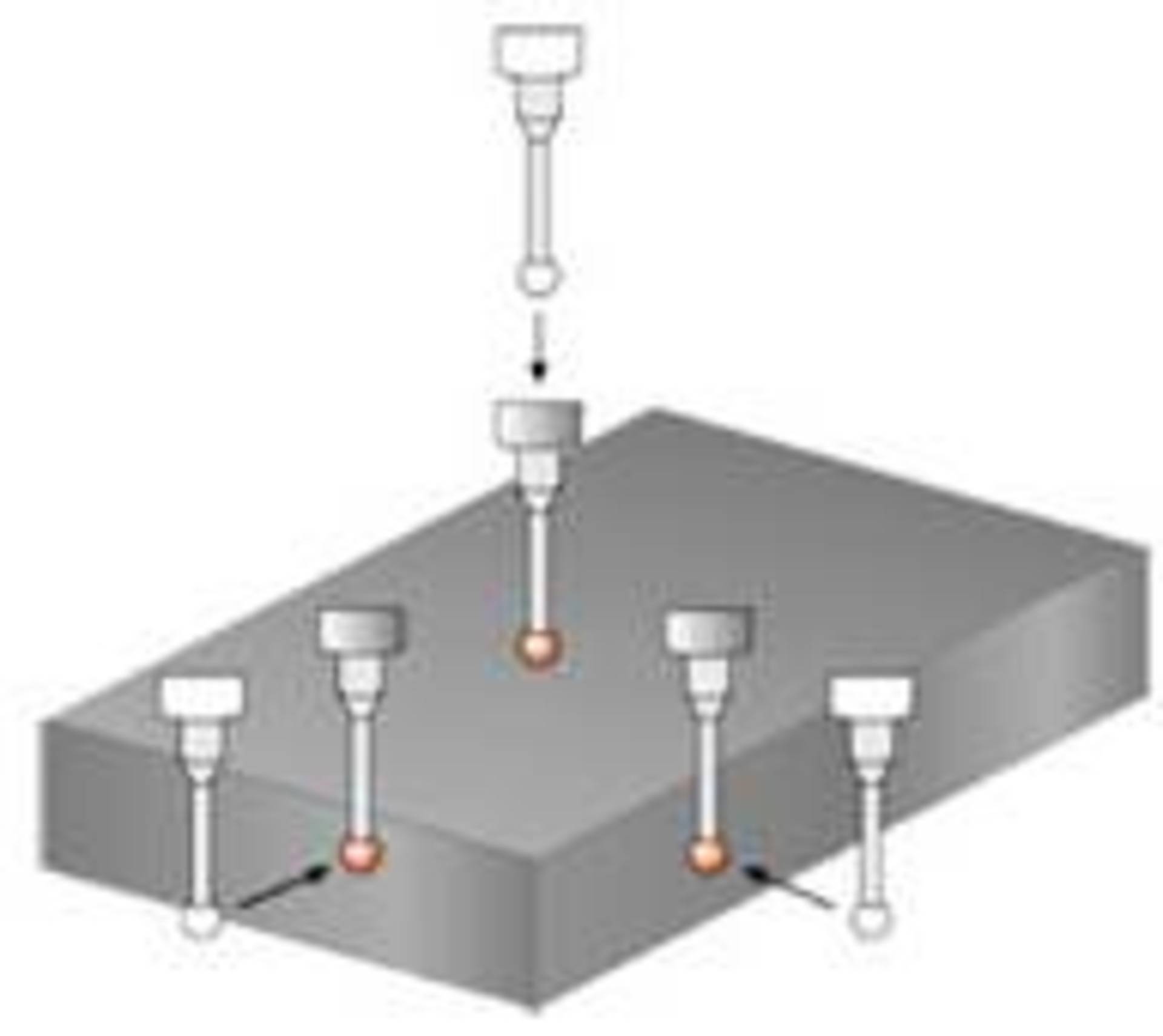

With the aid of the 3D probe, a measuring field is created in the Z plane in a freely definable grid dimension. This allows surfaces of workpieces or reference surfaces to be measured and deviations in the Z height to be recorded and automatically corrected. With the help of this technology, the dispensing needle is tracked according to the recorded unevenness, thus ensuring an optimum dispensing height at all times. The measuring fields can be saved and reloaded as required.

Advantages

- Less scrap

- Cost savings due to short setup times

- Higher quality machining results

Applications

- Precise depth machining even with existing material or clamping tolerances

- Precise measurement of workpieces in X, Y, Z direction

- Precise machining even of curved surfaces

Sensor XYZ - Genial in jeder Dimension

Der Sensor XYZ ist ein dreidimensionaler Tastsensor. Mit seiner Hilfe reduzieren Sie die Einrichtzeiten Ihres Bearbeitungssystems erheblich. Sie erhöhen die Genauigkeit und Zuverlässigkeit Ihrer Referenzierung. Der Sensor XYZ führt Ihre Produktion zu mehr Wirtschaftlichkeit. Langes und mühseliges Einrichten gehört der Vergangenheit an.

Corners and Edges

One measurement can be used to determine a material edge or the material height. With three measurements, both the material height and the exact position of a right-angled workpiece edge are determined.

Advantage: Much more precise determination of reference points on workpieces in a fraction of the time of conventional methods.

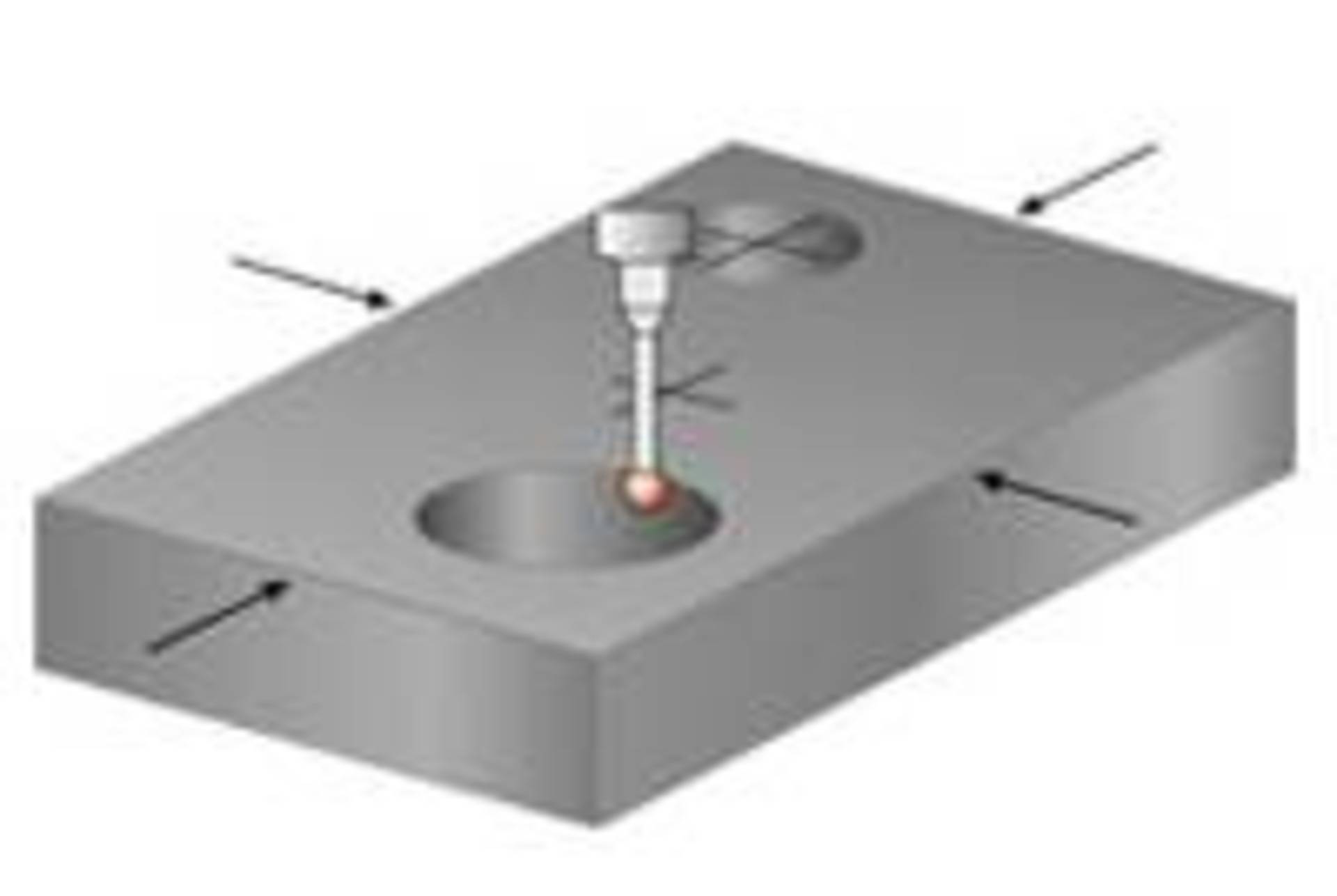

Center points

Center points of circular or rectangular materials or cutouts can be determined automatically.

Advantage: No long set-up times, precise centering on the material in a few seconds, compensation of an angular clamping.

Material surfaces

A material surface can be measured by point digitizing, and the dispensing program can immediately correct this measured height profile.

Advantage: Absolutely precise machining even of uneven or imprecisely clamped workpieces.

The 3D sensor consists of the measuring head with evaluation electronics, a swivel mechanism with precision bearing and the operating and evaluation software. The sensor can be used for referencing or measuring at lightning speed in every phase of machining. This is made possible by the fixed mounting on the Z-axis and the fast initiation of the measuring process by the swivel movement of the sensor from the rest position to the measuring position. After the measurement, the calculation takes place directly in the controller without any loss of time in real time.

DATRON offers the XYZ sensors in two accuracy classes:

Precision sensor TP-D

The TP-D type is designed for simpler measurements, e.g. to achieve constant dispensing heights. It offers a measuring accuracy of +/- 0.05 mm. The basic version of both sensors allows program-controlled Z-measurement. With the software extension "TP-3D", the CNC program is extended by additional cycles for edge probing and center point determination.

Precision sensor TP-R

Compared to the TP-D sensor, the TP-R sensor is characterized by lower probing forces and by a higher measuring accuracy of +/- 0.01 mm. Process reliability is increased with the TP-R probe, as it is attached to the housing with a magnetic coupling and thus yields in the event of excessive forces before damage to the probe occurs.