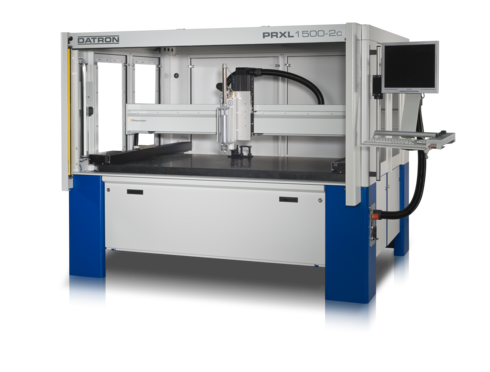

DATRON's PRXL series gantry dispensing machines are ideally designed for large-format workpieces and utility manufacturing. With the volumetric dispensing system of the PRXL series, DATRON offers a precise 3-axis gantry robot in a modular and compact design. Servo motors in combination with ball screws and our special control and regulation technology ensure high dynamics. Thus, dispensing speeds of up to 20m/min (333mm/s) are achievable and ensure the shortest possible cycle times. The user-friendly design of the PRXL systems as well as special dispensing accessories ensure minimal set-up and programming times, thus offering you high economic efficiency.

DATRON PRXL dispensing machines are available with different working ranges.