Clamping Systems for CNC

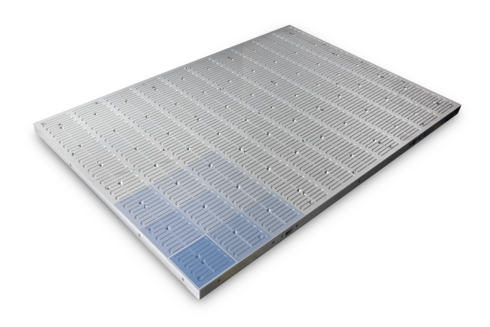

Plug & Play for Easiest Handling

Extremely simple and easy to use. Place your parts an be done! With the high holding forces of DATRON vacuum plates, even the smallest parts stay in place. The patented special cardboard VacuCard++ is the perfect sacrificial layer.

Moduar Clamping Technology

Economical production due to clamping within seconds

The end of time-consuming screwdriving and set-up times!

Economical manufacturing through clamping within seconds: DATRON's module clamping technology can significantly reduce setup times.

The end of long screwdriving and set-up times!

Economical manufacturing through clamping in seconds: Thanks to DATRON's modular clamping technology, you can set-up times can often be significantly reduced. Via conical centring sleeves, the module plates are directly mounted on the the machine table. This applies to all machines with integrated taper clamping system.

Thus, the clamping modules can be changed very quickly with a high reproducibility of the clamping position.

DATRON offers a wide range of finished module clamping solutions: Modular clamping plates with vacuum, T-slots with Short stroke clamping element, chuck or vice.

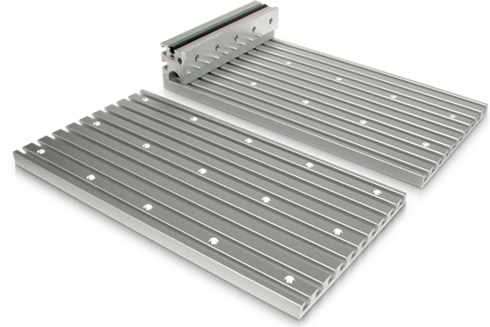

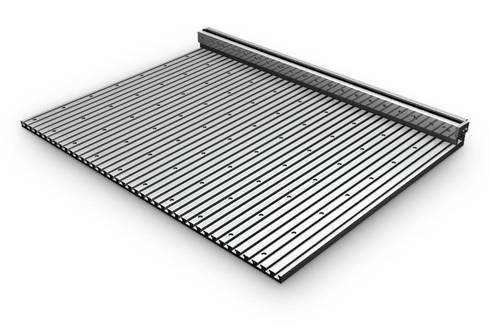

DATRON MS-TN T-Slot Module Clamping Plates

The T-slot module clamping plate offers space for application-specific fastening solutions or the combination of short-stroke clamping element and fixed clamping jaw.

The modules are mounted on the machine table with the vacuum suction system.

DATRON MS-TNA T-Slot Table Upgrade

To take advantage of the high flexibility of T-slot clamping systems, the machine table can be upgraded with four T-slot module clamping plates. The modules are attached with the vacuum suction system.

DATRON KSE Wedge Clamping Element|

The DATRON KSE wedge clamping elements can be configured for single as well as for multiple clampings. Due to clamping screw and T-nut, they can be flexibly used on the DATRON T-slot plate. Its compact design allows the work area to be optimally used.

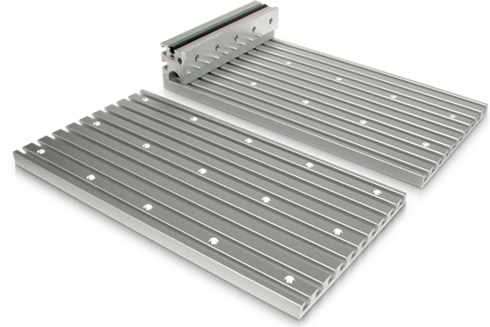

DATRON MS-P Module Clamping Plates

Clamping devices, such as vices or workpieces, can be fastened to module clamping plates. The modules are fastened on the machine table either with a screw connection or with the vacuum suctioning system.

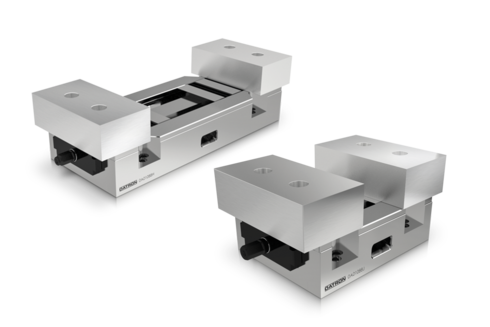

Compact vice

The encapsulated DATRON compact vice is 100% protected against contamination. Malfunctions due to contamination and jammed chips are a thing of the past. It is characterized by a low overall height as well as high clamping force. It is available with a guide length of 160 mm or 300 mm. Optional aluminum clamping jaws allow individual adaptation to component geometries.

Please feel free to contact me at any time!

If you have any questions or would like to know more about our high-speed milling machines, please do not hesitate to contact me.