Plug & Play for the easiest handling

Extremely simple and easy to use. Place parts - done! With the high holding forces of DATRON vacuum plates, even the smallest parts hold. The patented special cardboard VacuCard++ is the perfect sacrificial layer.

All DATRON machines can be equipped with DATRON vacuum clamping technology. Due to its specially developed design, this enables very high holding forces, even with shapes that are otherwise difficult to clamp and the thinnest plate materials.

Advantages

- Very short set-up times

- Time-efficient blank processing possible

- Deformation and vibration-free clamping of thin plates

- Complete milling and separating of workpieces possible

Application

- Clamping of plate materials

- Clamping of flat housings

- Clamping of difficult to clamp materials and shapes

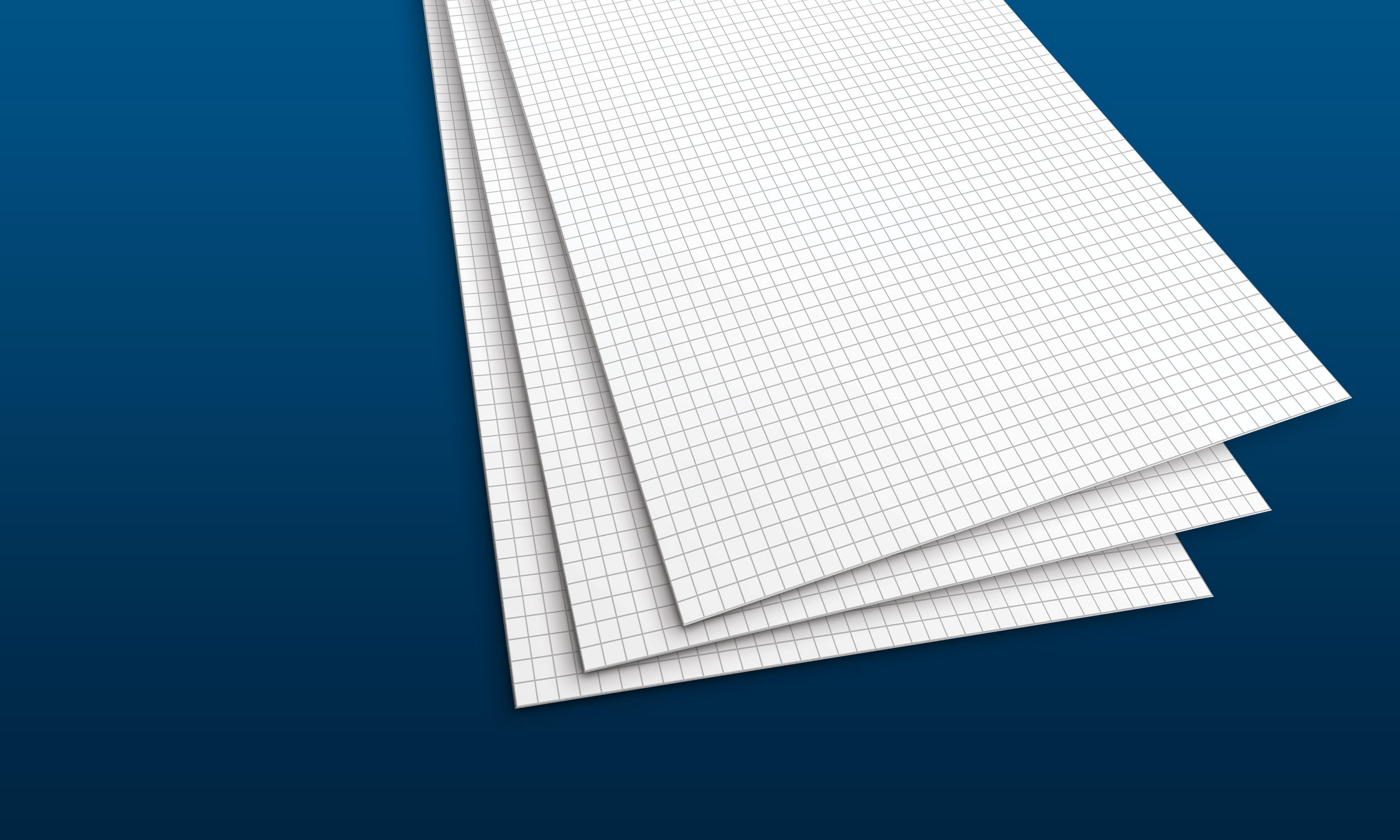

DATRON Meander Vacuum Plates

The vacuum is distributed via meander-shaped grooves arranged in 100 x 100 mm fields. These can be switched individually to optimally adjust the clamping surface and minimize leakage currents. This generates high holding forces, which enable efficient working.

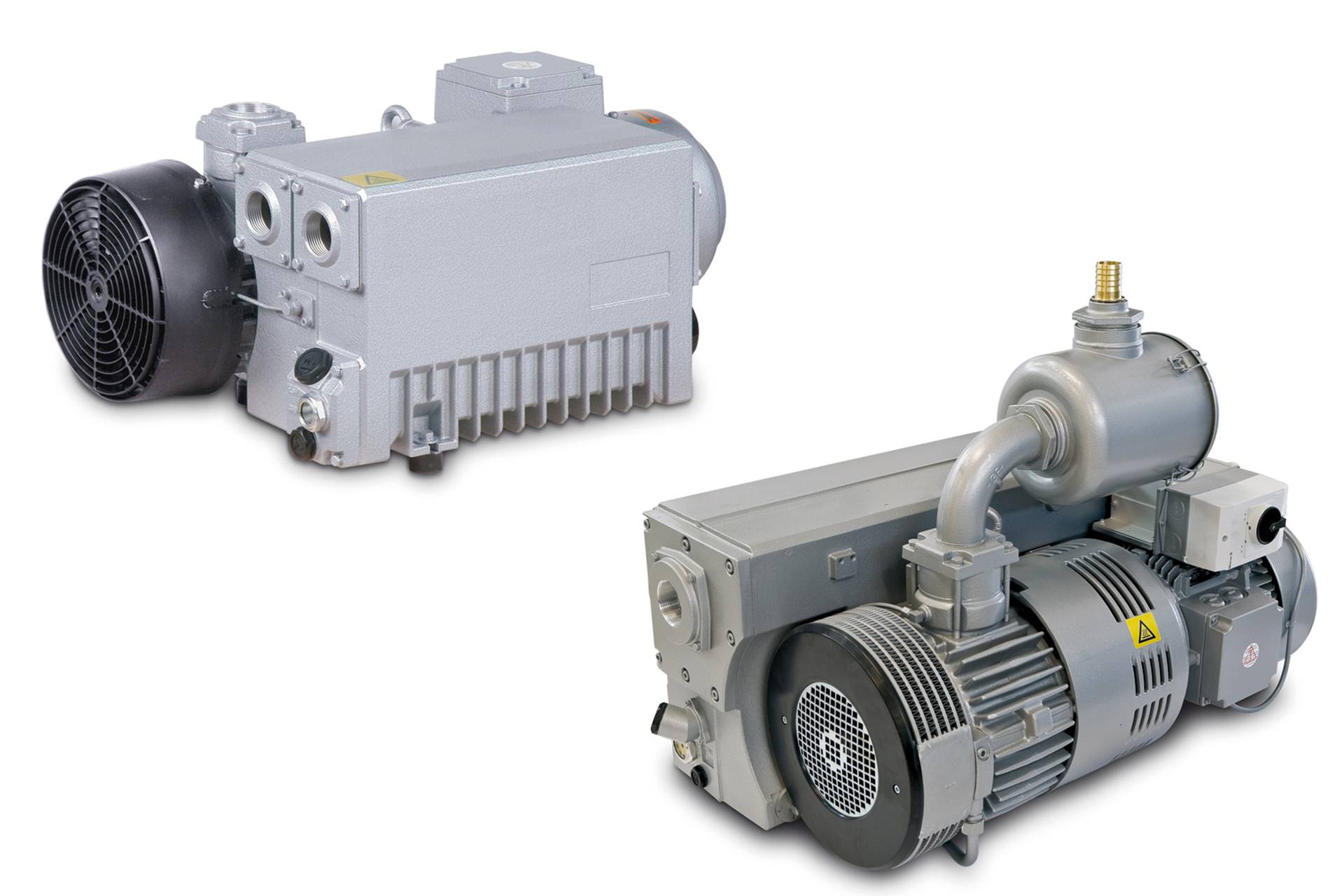

Vacuum pumps

DATRON offers the most suitable vacuum pump for each application. The required pump size depends on your clamping area and the vacuum plate.

Our expert staff will be happy to assist you in finding the right solution for your production!

DATRON VP-B-1/2

Scope of delivery:

- Rotary vane vacuum pump

- two fields vacuum distributor

- oil / air cooler

- Suction filter

- Suction side check valve

- Gas ballast valve

- Oil mist separator

- Motor protection switch

- Connecting hose

- Three-phase contactor

VacuCard++

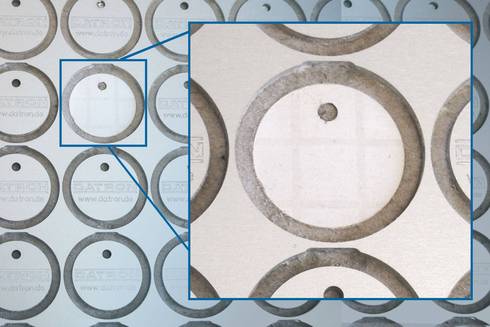

The VacuCard++ is a special cardboard layer patented by DATRON, which is placed as a sacrificial layer between the workpiece and the vacuum plate. In contrast to the DATRON VacuCard, the VacuCard++ has an additional grid-shaped sealing adhesive layer, which significantly improves the holding property during vacuum clamping and at the same time significantly reduces the vacuum loss.

Discover our DATRON VacuCard in our online store

* the store is only for German customers. If you are interested in our DATRON VacuCards, you are welcome to contact us at any time by phone or e-mail.

When should VacuCard++ be used?

- Milling of small parts that are to be milled out of sheet material

- Blank machining without separators

- Milling of thin and soft sheet material

- Milling of sheet material with rough surface

How does the VacuCard++ work?

- Clamps very small parts: The sealing adhesive layer holds parts that are so small that the holding force of the vacuum alone is no longer sufficient

- Increases the holding forces during vacuum clamping due to the suction cup effect of the grid-shaped sealing adhesive layer

- Prevents the workpieces from slipping away when large milling forces are applied by the sealing adhesive layer (coefficient of friction is drastically increased)

- Reduces vacuum consumption: throttling effect due to limited air permeability and by covering the areas not required with a protective film

- Distributes the vacuum evenly over the workpiece

- Prevents premature collapse of the vacuum on the workpiece when milling around or drilling holes

- Holds workpieces with rough or textured surfaces: the sealing effect of the sealing adhesive layer prevents foreign air from being drawn in

- Prevents the edges of soft and flexible workpieces from lifting off

- Enables residue-free removal of the machined workpiece from the VacuCard++

Place the VacuCard++ with protective film between the vacuum clamping plate and the workpiece. Use a pico knife to cut out the protective film on the edges of the workpiece. Pull off the cut-out protective film and place the workpiece on the exposed VacuCard++. Now switch on the vacuum and start the milling process. After milling, you can immediately remove the workpiece from the VacuCard++.

DATRON application tips: For very small workpieces, we recommend placing the workpiece on a completed diamond of the VacuCard++ if possible. When separating, if possible, completely mill around the workpiece to 1/10 mm and only separate the workpiece in the last operation, with careful feed. If possible, turn off the cooling/lubrication before the last operation.

Technical data

- Cardboard with redundant suction effect due to latticed sealing-adhesive layer

- Combination of adhesion and vacuum clamping

- Reduced vacuum consumption due to limited air permeability and by covering with protective film

- Disposal in paper waste

Please feel free to contact me at any time!

If you have any questions or need more information about our CNC accessories or our machines, please do not hesitate to contact me.