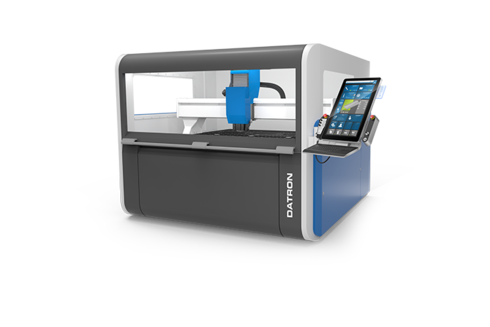

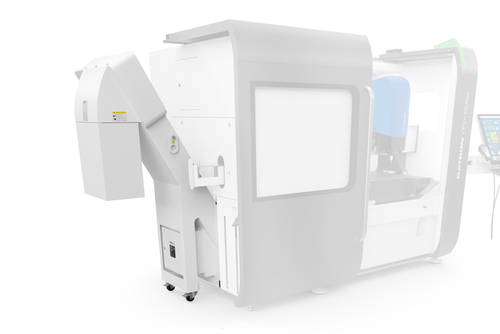

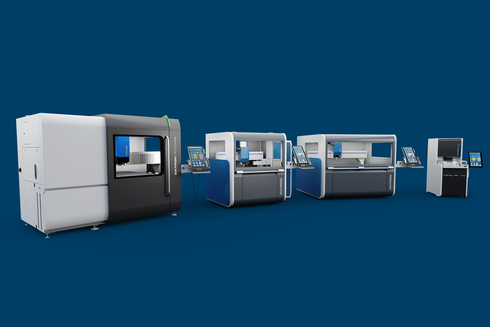

Welcome to the DATRON world of CNC Machines

DATRON high-speed milling machines impress with their predominantly light and compact design. With a DATRON milling machine you get maximum working space compared to the required footprint and a real expert when it comes to achieving precise, post-processing-free workpieces especially made of light materials, such as aluminum, non-precious metals, wood, plastics or composites.

DATRON Used CNC Milling Machines, Dental Milling Machines and Dispensing Machines

We are also your reliable partner in the area of used machines. We offer you as new and factory-upgraded DATRON used machines, which increase your productivity from Day 1 onwards.

We are available for a detailed and individual consultation.

Please consider that used machines cannot be allocated.

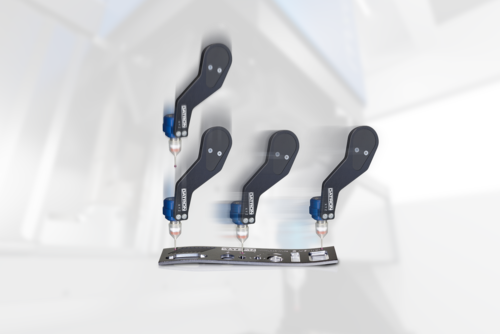

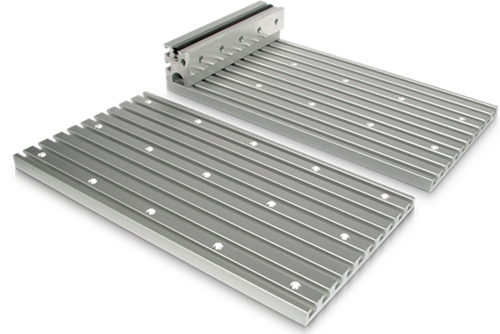

DATRON Automation Portfolio

The smart DATRON automation portfolio offers efficient and customized solutions for future-oriented production purposes. Automatic front and side doors, interfaces to internal hardware, external automation and also software interfaces and solutions are add-ons to DATRON machine systems with DATRON next Control for state-of-the-art production processes and complete the product range.

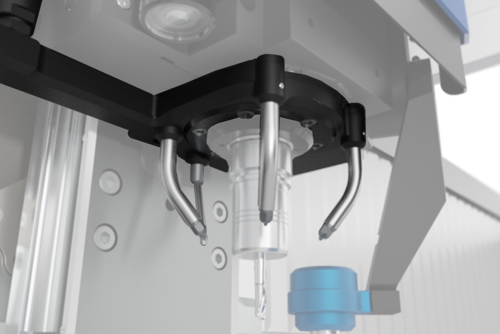

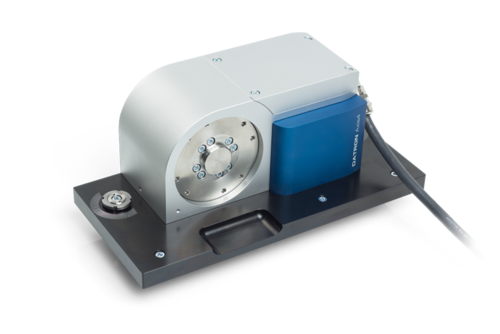

ToolAssist

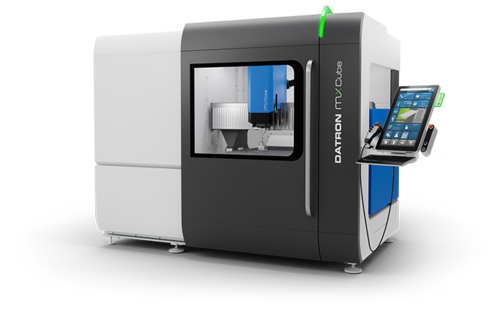

DATRON ToolAssist, with its unique tool change system, is available for the high-speed milling machines DATRON MXCube (already integrated), DATRON M8Cube and DATRON MLCube with DATRON next control.

Please feel free to contact me at any time!

If you have any questions or would like to know more about our high-speed milling machines, please do not hesitate to contact me.