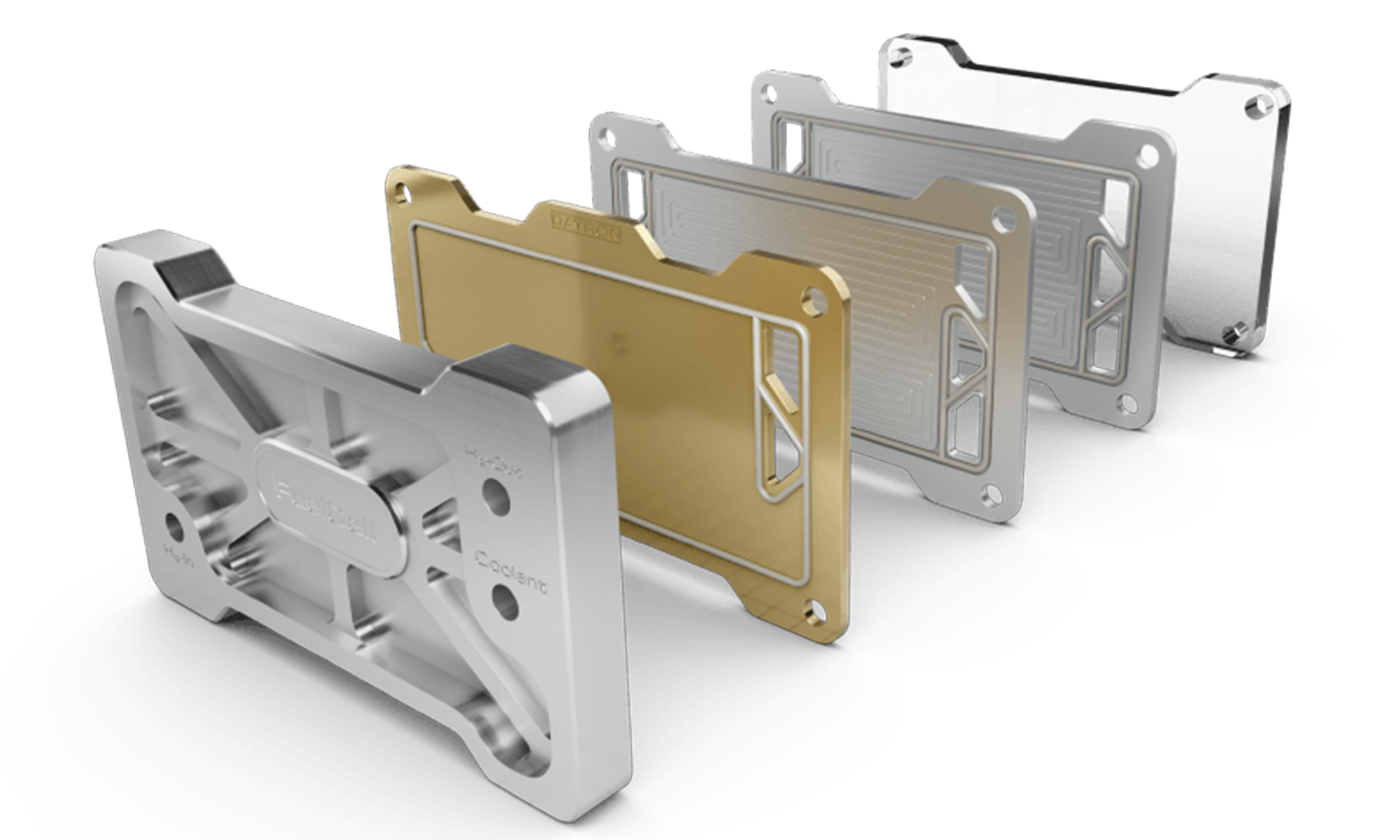

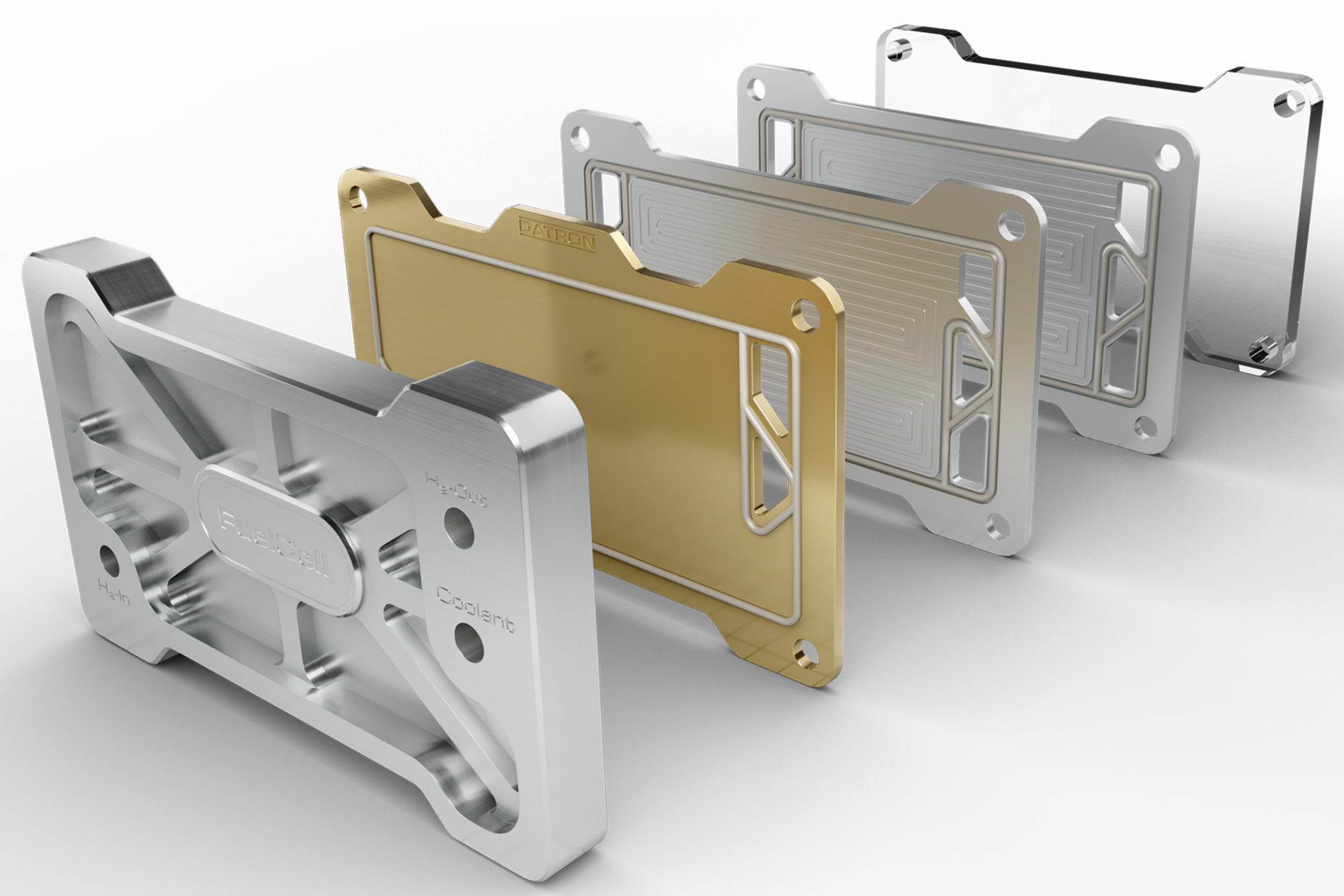

High process reliability, maximum flexibility and scalability have been the main pillars of DATRON technologies for many years and are the best prerequisites for fuel cell manufacturing. The DATRON fuel cell is composed of four components, which can be manufactured precisely and with high quality with DATRON machines.

End plate

Lightweight construction with high stability at the same time. Large pockets symbolize these component properties and demonstrate the strengths of DATRON milling machines in plate machining. Efficient production of components with high metal removal rates - from prototype to series.

Current collector

Benefit from the flexibility of DATRON milling machines. Fast, accurate and contour-true milling in a wide range of materials.

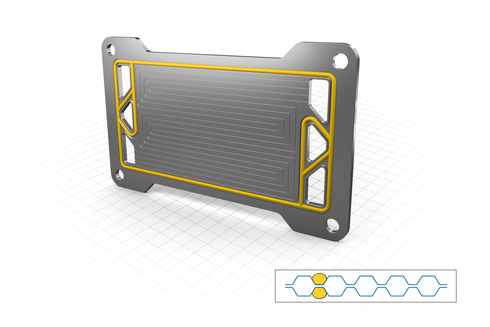

Bipolar plate seal

DATRON dispensing systems convince with short cycle times at high process reliability and offer the optimal conditions for the production of bipolar plate seals:

- Highest quality and precision

- Freely programmable dispensing quantities

- Cost-effective production

Acrylic cover plate

Tightness with visual inspection. The acrylic cover plate allows the compressed seal to be viewed in the assembled fuel cell model.

NOTICE:

The DATRON fuel cell shown does not represent a functioning fuel cell. It serves as a model for the best possible demonstration of DATRON technologies.

Maximum flexibility and scalability with short setup and cycle times

The objective for the processing of the bipolar plate seal is a short cycle time with high process reliability. For this purpose, volumetric dispensing heads and software specially developed by DATRON are used. In liquid sealing, a special focus is placed on the ideal

mapping of the critical start/stop zones. With DATRON dispensing systems, no significant thickenings and increases occur precisely in these areas.

Freely programmable metering quantity over the entire metering bead contour, enable a homogeneous sealing height, even with structured surfaces

Material preparation guarantees bubble-free gasket application and, together with the possibility of component measurement, makes a significant contribution to process reliability

- High repeatability and precision of the machines

- High-quality axis systems from the CNC range

- Low-maintenance machine systems

- No costs for tools, therefore economical even for very small quantities

- Small gasket width enables compact design

- Easy gasket application in grooves