Everything at a glance

- Tile design with self-explanatory icons

- Realistic 3D graphics

- Current machine status is visible on run screen even from a distance

Easy handling

- Intuitive touch operation, similar to a smartphone

- Camera-assisted setup via swipe gestures

- Intuitive App-style functions

Produce your ideas quickly

- Fast, simple process

- Just 4 steps to the finished workpiece

- Compatible with leading CAM suppliers

- Additional data from CAM usable

SPACE SAVING

DATRON neo is extremely space-saving. It fits through all standard doors and uses only 1 square meter of your production space.

STABLE

The aluminium table on a machine frame made with a solid polymer concrete casting ensures stable and low-vibration machining. Using DATRON neo you achieve workpieces with consistent surfaces and precise milling details.

Interior

Your tools fully under control

With DATRON next tool management, you have tools fully under control. It gives you a quick and detailed overview of the type, diameter, cutting edge length and where the tool is located. Using the DATRON next filter function, you can find the tool you are looking for within seconds. All DATRON tools and their parameters are stored in the tool management system. This saves you time-consuming manual entry of milling cutter data.

24-station tool magazine

The automatic tool magazine holds up to 24 tools with direct shank clamping. A length sensor (diameter 14 mm) for automatically measuring the tool length is integrated. The optionally available cover minimizes the penetration of chips into the tool magazine and thus reduces the time required to clean the tool holders.

Spindle & Cooling System 2kW, 40,000 rpm Spindle

When small tools are used for machining, high speeds are required in order to manufacture high quality workpieces in a cost-effective manner. DATRON neo features a 2kW high-frequency spindle for speeds ranging from 4,000 - 40,000 rpm. This spindle runs smoothly, delivers high-quality milling results, and can be used for a wide range of applications.

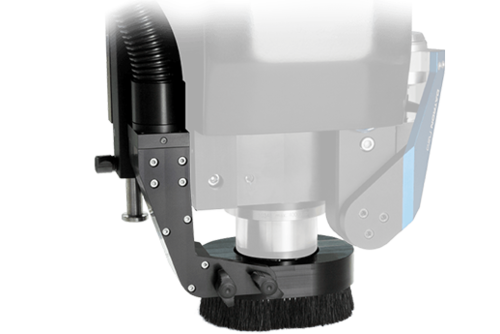

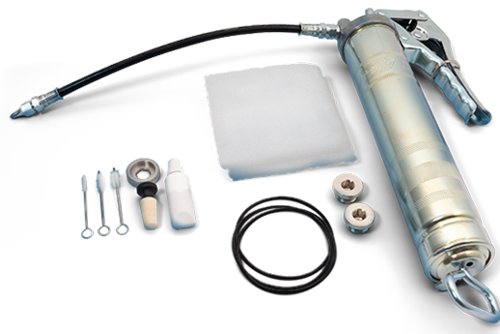

Minimum Quantity Coolant System

DATRON's Minimum Quantity Coolant System (MQCS) is differentiated by its extremely low coolant consumption. It sprays a fine mist to cool and lubricate the cutting tool. Using small amounts of coolant, operational and consumable costs are substantially lowered. The MQCS minimizes the time consuming and expensive maintenance issues associated with flood-type coolant systems. It is a highly-effective method of cooling and can reduce or even eliminate degreasing and disposal costs.

Touch Gestures

With this future-oriented control system, we make milling easy for beginners and professionals. Simply control DATRON neo with familiar touch gestures you use on your smartphone.

Easy Part Location and Job Set-Up

Both job setup and part location are easy due to the integration of a 3D Probe and a Camera included as standard equipment with DATRON neo. Using a familiar swipe gesture on the touch screen (similar to using a Smartphone), the camera will recognize and locate the part. Then the 3D probe will measure the part to ensure precision during the milling process.

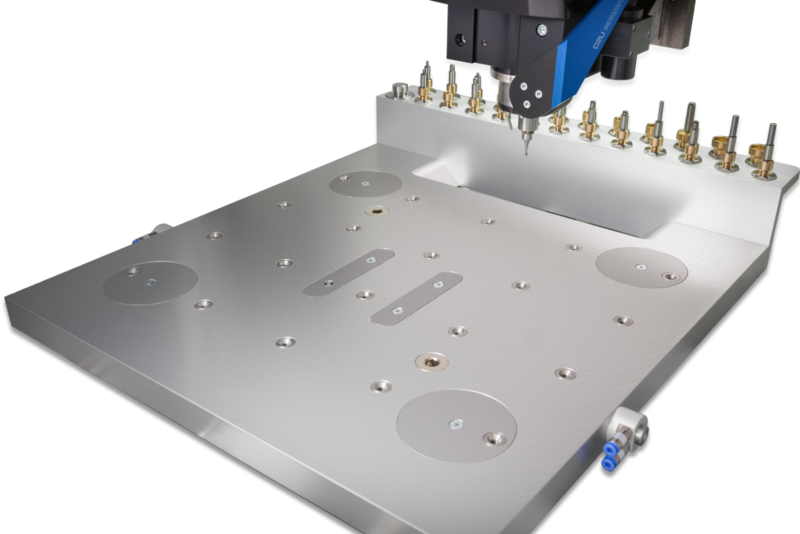

DATRON neo offers you full flexibility in the machining area

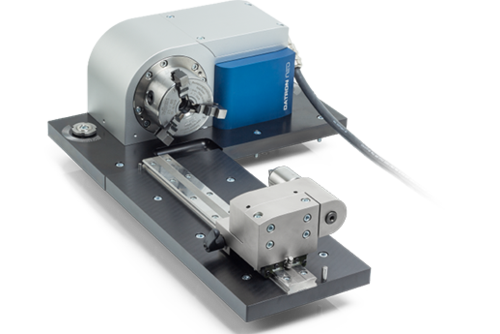

Conical System

Whether centric clamps, jaw chucks, special devices or rotating axes, DATRON neo offers you full flexibility in the machining area. The possibilities when clamping workpieces are as varied as your projects and applications. Tapered bores with threaded inserts in 100mm pitch allow fast, accurate and repeatable workholding using different clamping technologies.

Here's how it works. Conical cavities are milled by the machine itself on the surface of the machining table. This results in a “boss-in-cavity” system that accommodates centering inserts on the bottom of our workholding (part fixturing) units. This ensures location repeatability. So if you’re milling batch of parts and an unexpected rush project comes in, just remove one fixture and replace it with the new job. When the rush job is complete, return the first fixture to its place and pick up where you left off. DATRON workholding solutions include:

- Jaw Chuck

- Centric Clamp

- Pneumatic Clamping System

- Vacuum Table (Chuck)

- Rotary Axis

- T-Nut Table

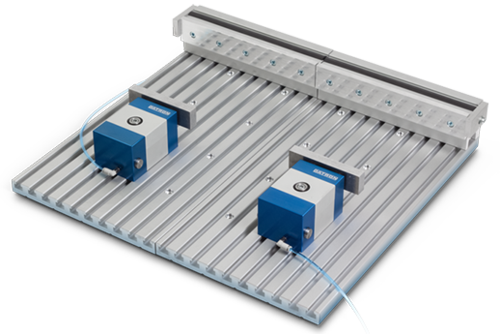

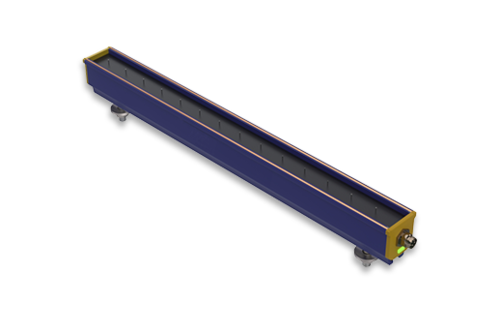

Vacuum Connection

DATRON vacuum module clamping plates offer maximum clamping force and ease of use, achieved by DATRON's unique vacuum distribution. Two vacuum plates specifically designed for DATRON neo are operated separately via connectors recessed in the worktable. Each plate is subdivided into 10 segments that - depending on component size - can be activated individually.

To distribute the vacuum optimally below the workpiece, we have developed the DATRON VacuCard, a special cardboard, that serves as a sacrificial layer. With VacuCard, you can mill through holes (through the workpiece) without damaging the machining table.

Conical Connectors

A boss-in-cavity system for lightning-fast setup of your workholding – whether it's a jaw chuck, a pneumatic clamp or a vacuum table . Just set it down, lock it in and start milling. This system guarantees position and repeatability!

Service Port Cover

Easy accessibility to grease ports on the Y axes. No crawling under the table or getting dirty - everything is within reach!

Flexibility for multiple setups

Whether your application calls for centric clamps, jaw chucks or rotating axes, DATRON neo offers you full flexibility to integrate them into the machining area. The machining area is 19.5" x 16" (X x Y) – so, the possibilities for clamping workpieces are as varied as your projects and applications. Tapered bores with threaded inserts in 100mm pitch allow for fast, accurate and repeatable workholding using different clamping technologies.

Stable Construction

DATRON neo has an aluminum bed on a machine frame made with a solid polymer-concrete casting. This rigid construction ensures stability and low-vibration machining. With DATRON neo, you produce workpieces with consistent surfaces and precise milling detail.

Exterior

Easy-to-Use ... but Smart at the Same Time

Smart Milling. That is what defines DATRON neo. The entire machine, interface and software was designed from the ground up to deliver the ultimate user experience ... and high quality milling results at the same time.

Full Control At Your Fingertips!

With this future-oriented control system, we make milling easy for beginners and professionals. Simply control DATRON neo with familiar gestures you use on your smartphone.

EVERYTHING AT-A-GLANCE

- Tile design with self-explanatory icons

- Realistic 3D graphics

- Machine status is visible on the run screen even from a distance

EASY HANDLING

- Intuitive touch operation, similar to a smartphone

- Camera-assisted setup using finger gestures

- App-based functions

PRODUCE YOUR IDEAS QUICKLY

- Fast, simple process

- Just 4 steps to the finished workpiece

- Compatible with leading CAM suppliers

- Additional data from CAM usable

Small Footprint. Huge R.O.I.

DATRON neo requires an installation area of just one square meter and is therefore an extremely space-saving production system. With dimensions of 80cm / 130cm / 190cm (32" x 51" x 74") this machine fits through a standard door.

With DATRON neo, milling is easy and efficient. Milling strategies like pocketing, chamfering, thread milling and creating 3D forms can all be performed quickly using this 3-axis compact milling machine. Prototypes made of composites, engineered plastics, metal or wood are produced quickly and with a consistently high quality.

Our Customer Care and Service team provides world-class support – from installation and training through maintenance and consultation ... for many years to come.

Our Smallest Machine. Your Biggest Competitive Advantage!

DATRON neo is a compact easy-to-use 3-axis milling machine that has it all. Flexibility, dynamics, performance and quality – all housed in the smallest possible space.

DATRON neo is extremely space saving. With its dimensions of 80cm/130cm/190cm (32" x 51" x 74"), it fits through a standard door and uses only 1 square meter of your production space.

The machine weighs approximately 700kg (1,543 lbs.). Its rigid frame is made of cast polymer concrete and is supported by adjustable feet, which allow for easy leveling.

Chiller & Microjet (Under the Hood!)

Space saving is pushed to the max with DATRON neo. Critical components like the Chiller and Microjet, which would usually take up extra space outside of the machine footprint, are conveniently stored inside the machine chassis.

The Chiller Unit is used to maintain lower operating temperatures for the high-speed spindle. This extends the life of the spindle bearings and also maximizes accuracy by reducing thermal growth.

The Microjet is a high-pressure, but low-volume, coolant system that allows for misting of various coolant types such as ethanol, oil, water-soluble coolants and others.

Full Access to the Work Table without Bending

Need to set up or remove parts? When DATRON neo not in the milling mode, the table moves forward to provide easy access to your workpieces and workholding. This allows for extremely fast job setup and changeover – not to mention superior ergonomics for a healthy back!

Plug&Play Principle

DATRON neo was specifically designed and purpose-built to give you an easy and affordable entrée to high-speed milling. This Plug-and-Play system features the new DATRON next software which gives you full control of 3-axis milling without requiring years of experience as a machinist.

With DATRON neo you receive a high performance out-of-the-box system, that contains numerous hardware and software highlights. The 24” multi-touch operating display, the 3D probe, the integrated (machining area) camera, the 24-tool magazine and the 2kW spindle with minimum-quantity coolant system – all allow you to perform fast, high quality machining from Day One.

Installation

Unpacking, commissioning and setting-up the DATRON neo is so simple that you can do it all by yourself. All you need is a standard pallet truck. Of course if you need consultation or support in placing your machine, DATRON Customer Care is always here to help. We can schedule installation and training so that you're making parts right out-of-the-box.