Homescreen

All screen elements are clearly displayed and can be operated by swiping and touch gestures. It´s easy to use as a smartphone.

Run Screen

You monitor the progress of the milling program in the run screen.

The run screen gives an overview above the most important parameters such as spindle speed, feed, spindle position, vacuum and pneumatic pressure.

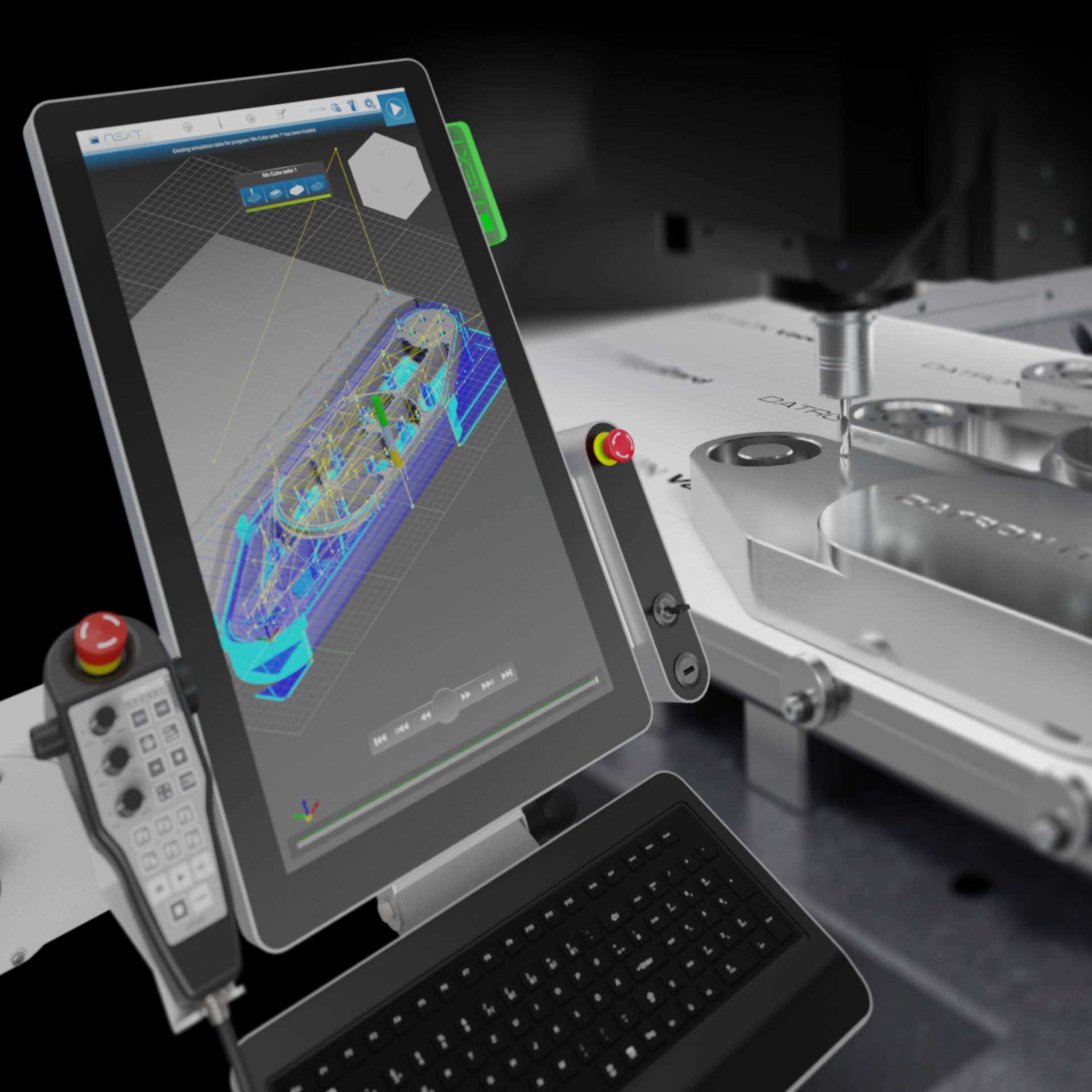

3D Simulation

In the 3D simulation, the workpiece is reproduced almost to the original.

So you can evaluate in advance whether your workpiece can be machined in the desired quality by the DATRON machine.

Program Management

With the DATRON next program management system, you load the milling program provided by your CAM system via a network or a USB device. The DATRON next program management system visualizes the data of each existing component, allowing you to quickly select and load a component.

Tool Management

With the DATRON next tool management functionality everything about tools is handled. The system gives you detailed information about the specific type, the diameter, the flute length and where the tool is located.

The DATRON next filter function allows you to find a specific tool within seconds.

Workpiece Setup

The correct setup of the workpiece, including establishing a zero point for orientation in the machining area, is one of the basic requirements for excellent machining results.

DATRON next supports your setup by combining swipe gestures with an interior camera and a 3D probe. Even without any previous milling experience, you can intuitively set up your workpiece perfectly.

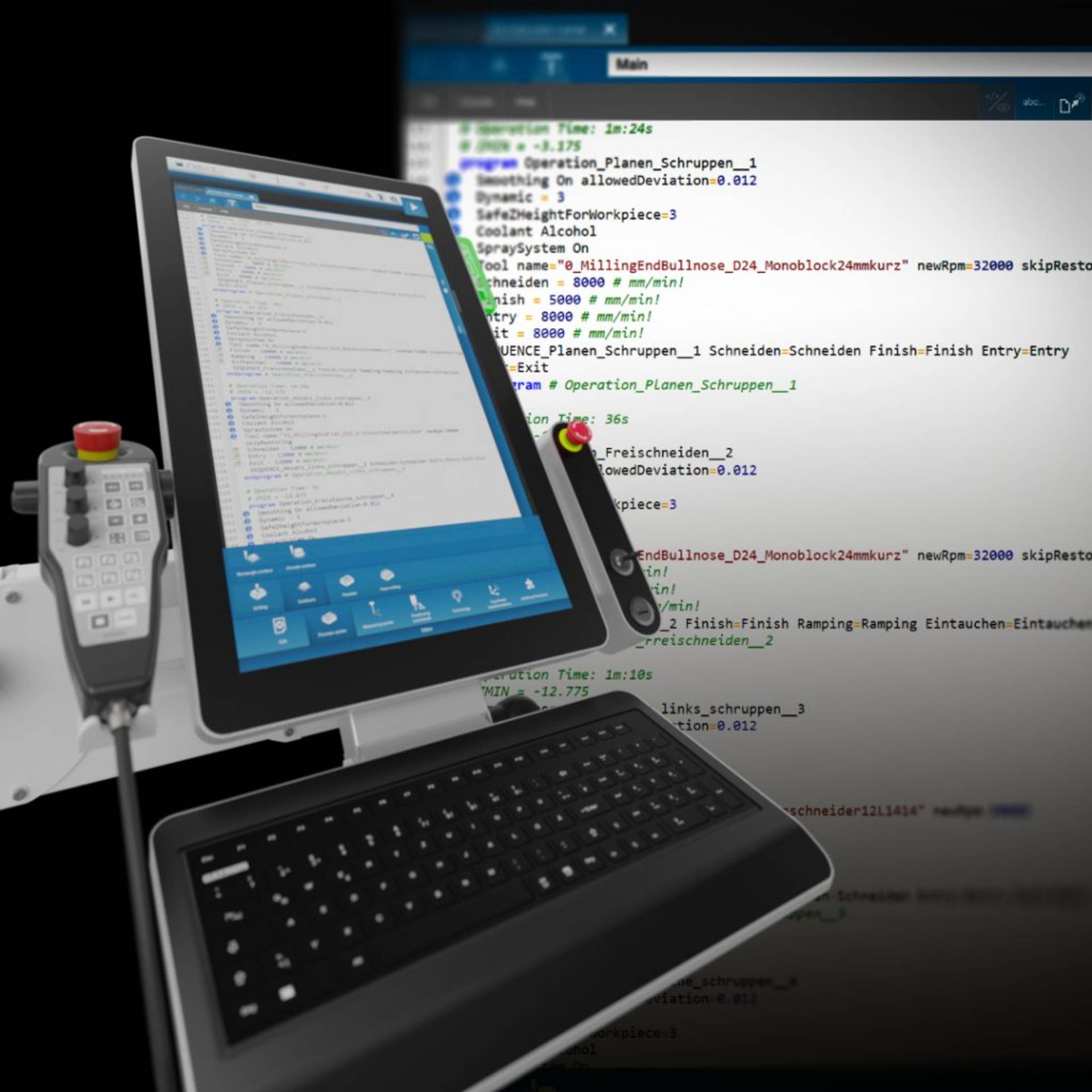

Editor

In the editor, you can program complex milling programs including loops, etc. For beginners, the graphical input mask is available, which translates completely into the respective user language.

Manual Operation

Unless you are working with a CAM system, simply use the manual control functions of the DATRON next after setting up the workpiece.

In a clear menu you have direct access to the most important cycles such as pockets, contours, holes and much more.

Automatic Pauses

You know that? When entering programs you can not stand permanently on the machine.

In the DATRON next simply activate a corresponding auto-pause and the machine stops in particularly important places in the program. So you can pursue other activities with a clear conscience.

Language

Your machine operators are international as your customers and would like to switch to a different interface language during operation?

No problem! In the drop-down dialog, everyone can select his personal language. All controls switch immediately.

CAM-Assistant

With the help of the CAM wizard, the DATRON next guides the user in 4 simple steps from the CAM program to the finished workpiece.

Including easy setup with the camera and swipe gesture as well as an automatic tool check.

Tool Check

The special tool-check function checks all tools(predetermined by the CAM system) and compares them to those already existing in DATRON machines. So, you get a quick overview of the tools available and those still required – with appropriate suggestions for alternatives.

Surface Profile

The software function for creating a surface profile enables your machine to measure and automatically compensate for uneven areas and tolerances on the surface of your blanks.

Protected Areas

The software function for setup of protected areas enables you to define specific areas in the working area of the machine that are not approached by the tool.

For example, this prevents accidental milling into a mounted vacuum plate as a result of programming errors without having to make changes in the milling program.

Execute from cursor

If you want to start at a certain point in the milling program, simply mark the desired program line in the editor and start the execution directly.

Contour Smoothing

The contour smoothing calculates an optimally smoothed path within the permitted contour deviation. What makes a fast and contour-accurate milling possible.

Dynamic parameters

The dynamic parameters are used to define the required parameters. With the parameter “good surface”, for example, the production process is in the optimum ratio to the machine speed and the possible contour violations.

Update

Regular updates ensure the quality of the DATRON next software and provide the operator with new, helpful functions on an ongoing basis.