Benefit from our know-how and our product variety:

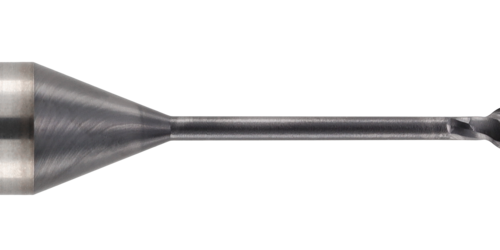

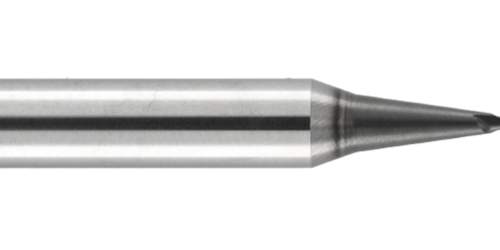

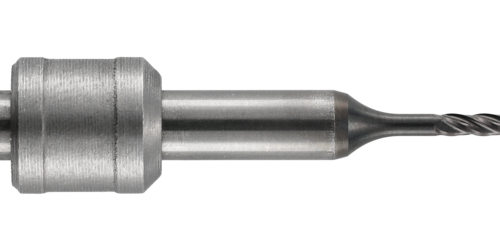

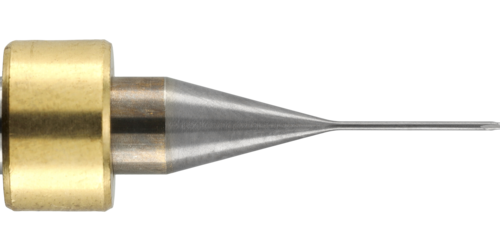

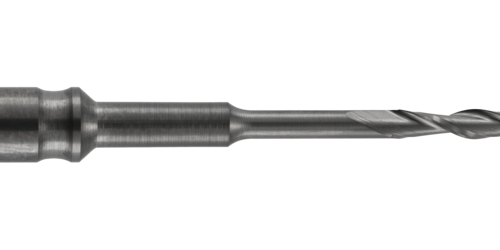

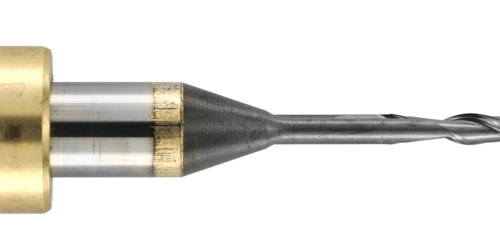

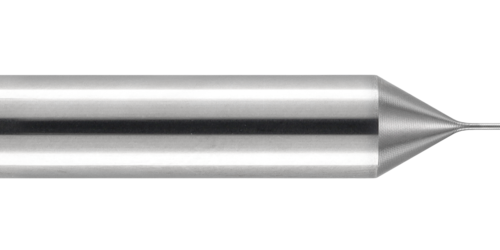

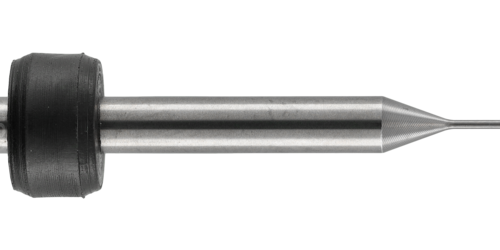

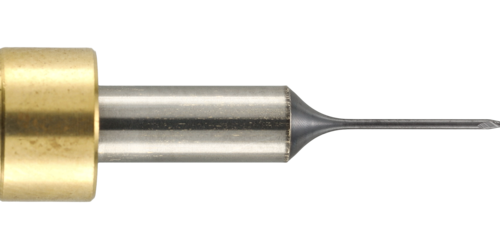

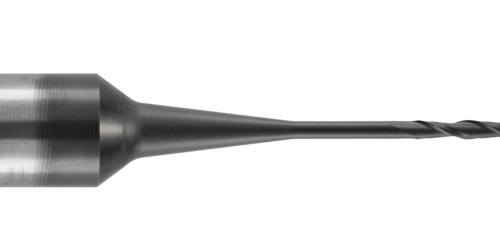

The manufacture of dental milling tools on state-of-the-art fully automatic grinding machines ensures consistently high quality and performance for your manufacturing process. Our carbide milling tools are compatible with a wide range of machines from other manufacturers. However, if you require a special tool that you can't find in our standard range, we can offer you the option of manufacturing individual end mills to your own specifications. Specially optimised for high-speed milling, the high-quality coatings, such as diamond or high-end coatings developed and refined in our company, are particularly wear-resistant

Dental Milling Tools

Discover our DATRON Online Shop

Note: Our shop is only for German customers

Tool Highlights

With more than 25 years of experience in the field of tool manufacturing, we now currently deliver over 350,000 cutters per year to more than 10,000 tool customers worldwide. More than 4,600 DATRON machines alone help our national and international customers, who appreciate our many years of machining expertise as a machine builder and at the same time tool manufacturer, to work productively and economically.

For your individual production requirements, we offer a wide variety of products in our comprehensive (online) range. Our milling tools are characterized, among other things, by the combination of excellent cutting edge geometries, optimum coatings and high-quality solid carbides.

For your production success in practice, laboratory and industry, we are constantly expanding our product range. Practice-related demanding milling tests in our own technology center create the basis for meeting consistently high production requirements in the long term. Thus, we can fulfill the quality promise "Made in Germany" - often underlined by the patenting of special DATRON cutting geometries - for you.

Our sustainability-oriented corporate structure is reflected in many immediately noticeable customer benefits for you:

- Fast delivery time and high availability

- Sound tool advice (both on purchase and in application)

- Individual tool service (special tools)

- OEM Business, Neutral or with Private Label

- Compatibility with all current dental milling machines

- Very good price/time/milling quality ratio