DATRON CNC solutions meet your requirements when it comes to milling,

drilling and engraving.

- High-speed spindles, up to 60.000 rpm

- Short set-up times due to DATRON clamping fixtures

- Flexible module clamping solutions

- Minimum quantity cooling/lubrication system

- Automatic tool changer

- Proprietary technology for high-speed machining

- Easy and quick programming

- Microsoft Windows-based control

- Optional automation solutions

- Very low energy consumption

Let our application samples prove the high quality difference!

Are you looking for the right milling machine with the corresponding milling tool for your application?

Our machines offer the highest precision and surface quality at an excellent price-performance ratio.

Milling, drilling and engraving - CNC systems for versatile applications

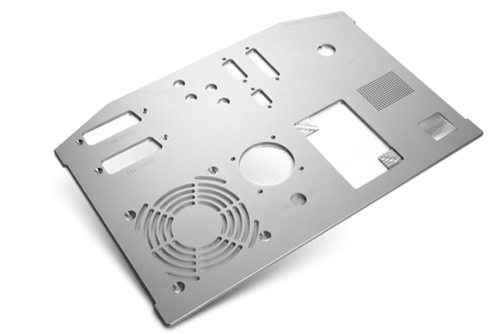

Front panels: For the precise and flexible production of front panels, it is crucial to be able to implement milling, contours, drilling, engraving or cutouts quickly and with high quality according to specific production requirements. With a DATRON machine, you have an advantage in both economic and technological terms when machining your individual front panel or component design - regardless of whether the material is aluminum, brass or acrylic.

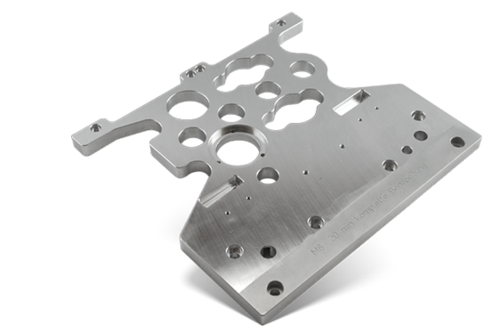

CNC machining: Our milling machines can be used for many applications and are characterized by their ability to deliver the highest quality in short production times. DATRON's technology strengths are particularly in the areas of 2D and 3D milled parts, micro-drilling, medical technology, aerospace industry and small molds.

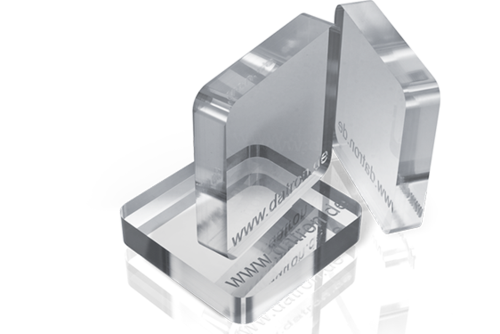

2D/3D engraving: Thanks to future-oriented CNC technology, our systems can easily process complex geometries or surface structures. Use our machines to realize 2D and 3D engravings in materials such as aluminum, brass, graphite or acrylic glass. Due to the new PerfectCut functionality, you will get absolutely perfect engraving results for various applications.

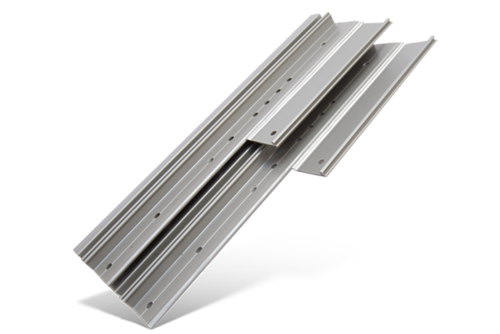

Aluminum profile machining: Our CNC machines use high spindle speeds, specially developed high-speed mini tools and low cutting forces to enable an almost burr-free cut. This results in minimal burrs when milling thin-walled aluminum profiles. In addition, we use advanced cooling and lubrication technology that is virtually residue-free.

Aluminum housings: With the versatile machine concepts of the M8Cube, M10 Pro and MLCube series, DATRON offers flexible solutions to machine even very large electronic housings made of materials such as die-cast aluminum, plastic and fiberglass-reinforced plastic. The robust design and advanced technology of the CNC machines allow you to implement the desired shapes, milling and contours with high accuracy.

Electronics manufacturing: Thanks to our many years of experience in electronics manufacturing, DATRON offers optimal solutions for high-precision milling, drilling, tapping and engraving for various applications - all in just one clamping. Manufacture electronic items such as notebook housings, PCB circuit boards, smartphone stands or speakers with our CNC machines.

Rapid Prototyping: With DATRON you can be sure that your prototypes will be manufactured quickly and effectively. Rely on our state-of-the-art CNC machines, our high-quality 3D control via Microsoft software, and our extensive experience in prototyping. Our CNC systems guarantee fewer design errors and better finished products.

Plate machining: DATRON is your reliable partner for plate machining. Thanks to granite table and ball bearing spindles, our machines offer you high precision, versatility and economy in the production of plastic, sheet metal and aluminum plates.

Acrylic/Plexiglas®: DATRON's milling machine technology provides you with the ideal solution for precise milling and engraving of acrylic and PMMA. Thanks to our integrated vacuum clamping technology, you can benefit from high holding forces. Your workpieces are securely and stably fixed in the machine, giving you precise and reliable results.

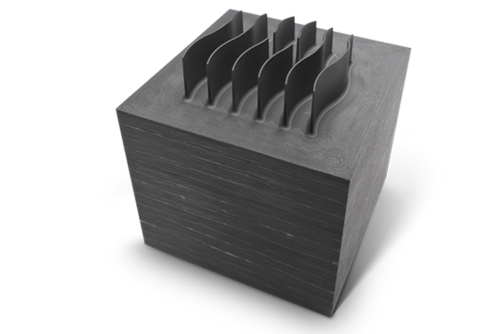

Graphite electrodes: Graphite electrodes not only offer an economical alternative, but also advantages in terms of machining and durability. For this purpose, use our C5 milling machine, which has 5 axes and is specially designed for milling small parts. With this machine, you can machine graphite electrodes precisely and efficiently and also obtain outstanding surface quality and accuracy.

Plastics machining: DATRON milling machines can mill plastics and composites with high quality and precision. Our machines offer a wide range of advantages that prove to be extremely versatile, efficient and economical in both prototype production and series production. Use our CNC systems for milling transparent plastics, plastic foams, composites such as PCB and GRP or plastics such as polyethylene, polypropylene and polycarbonate.