Dispensing Systems

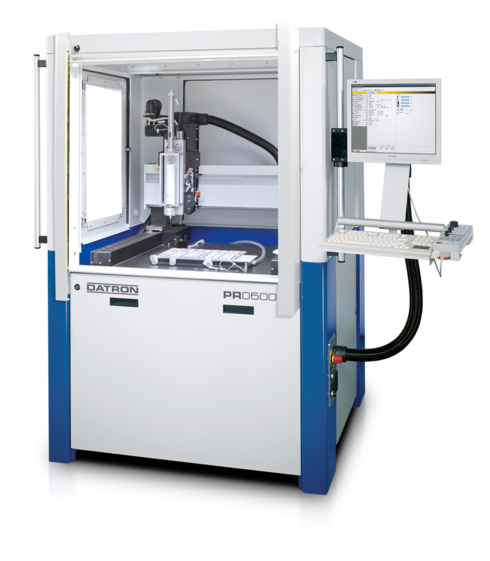

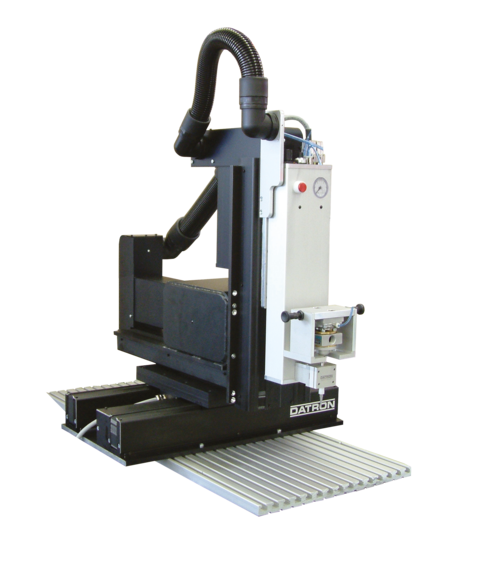

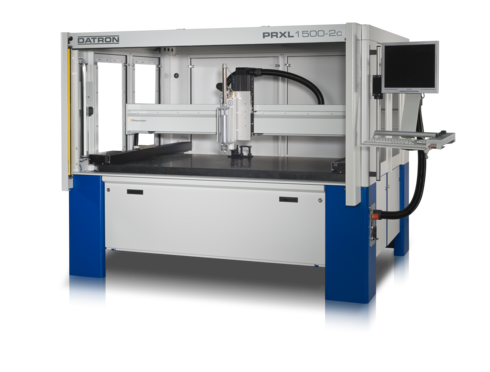

DATRON dispensing systems offer maximum process reliability and flexibility through the combination of the electronic dispensing head with the patented control and regulation technology. The use of special software technologies enables speed-independent dispensing and thus ensures high dispensing speeds with short cycle times. The systems work independently of pressure and viscosity, which is why there is no need to readjust process parameters due to changes in production conditions. In combination with the accessories specially developed for dispensing tasks, DATRON offers system solutions from "one source" that ensure optimum quality for your production.

PRECISE - DYNAMIC - (R)EVOLUTIONARY

NEW: DATRON evo 600

Experience the future of DATRON dispensing technology

- Customized to your needs

- Outstanding dispensing quality

- Intuitive control

- Impressive productivity

- Maximum flexibility

- First-class ergonomics

Get more information here