Your benefits at a glance:

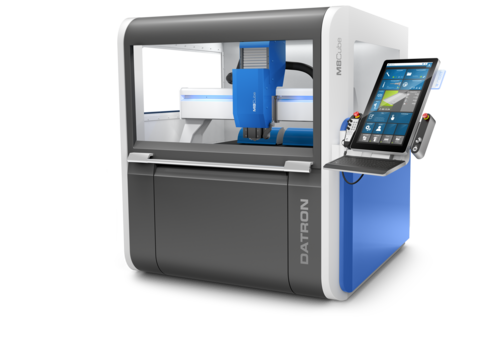

The M8Cube is one of the latest additions to our wide range of compact high-speed CNC machines for any milling requirement. New controls, new features, ergonomic working environment and low operating cost - let our range of accessories and software features prove the difference.

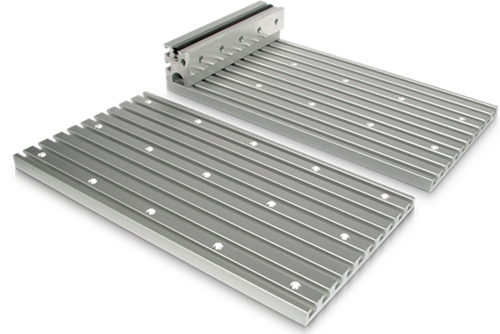

- Very large working area while keeping a small footprint

- Affordably priced with extremely low operating cost

- Short set-up times

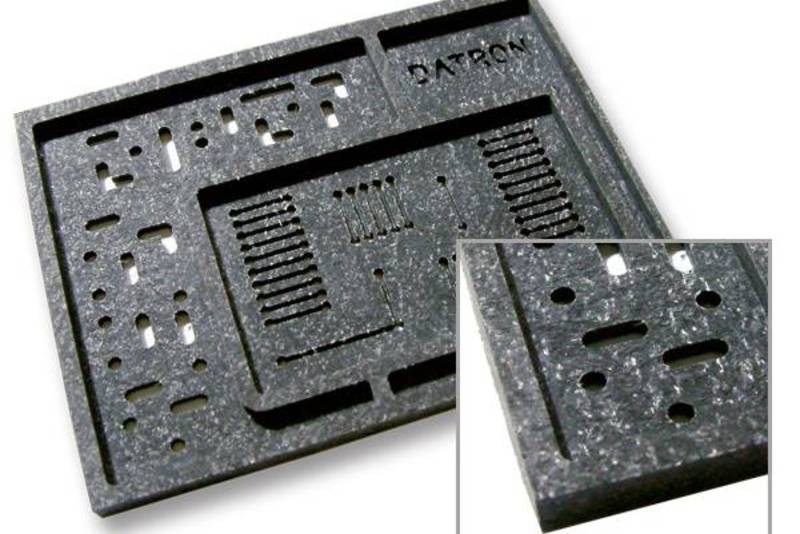

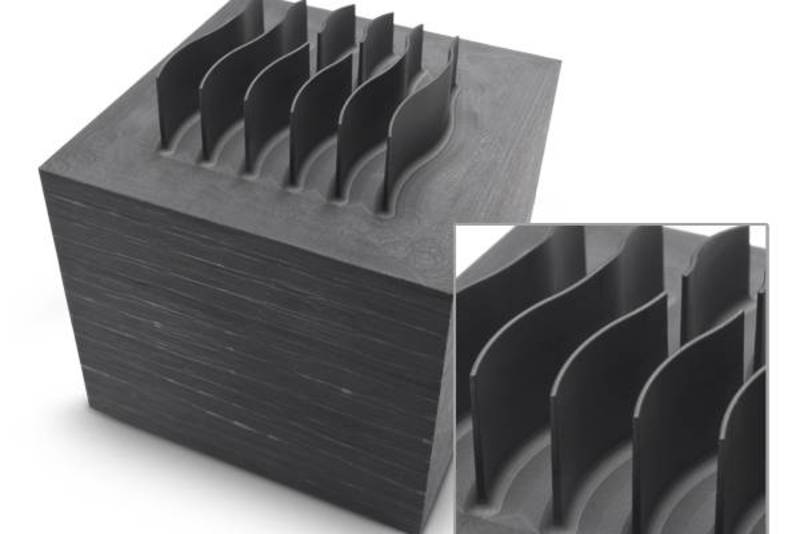

- You have new opportunities in milling, drilling and engraving. The M8Cube was engineered to process high-tech materials with small tools (Ø 0.1 mm to 20 mm)

The M8Cube is the top choice for the efficient machining of housings, profiles and panels made of aluminium and other nonferrous metals or cmposites. M8Cube stands for state-of-the-art milling technology "Made in Germany" for your production success.

DATRON machine software

A special highlight is the completely new developed (r)evolutionary DATRON next machine control. Some special features are smartphone-like operation via a 24" touch screen, automatic tool management, camera-assisted setup of zero points, very dynamic control for fast machining and perfect surfaces.

CAM Software

The "DATRON next" control works with generated milling programs of the standard interface DIN/ISO. In order to be able to use the full range of functions of the next control, however, we recommend an individually created postprocessor.

Please ask your CAM manufacturer for this. Our experts from the application technology department will be happy to support you in creating and optimizing the postprocessor.