Energy-efficient machines and economical resource utilisation are playing an increasingly important role in production processes. Thanks to their innovative lightweight design and energy-efficient drive technology, DATRON machines are already cost-effective. DATRON milling machines consume less than 2.7 kWh on average, even when required to deliver a high level of cutting performance. In addition, the minimum-quantity cooling lubrication system developed by DATRON is an extremely cost-efficient, environmentally friendly solution.

Integrating DATRON high-speed milling technology means investing in a rationalized, qualitative and profitable production with the added satisfaction of acting for the future by limiting the consumption of resources.

Resource- and energy-efficient

Example of the energy consumption of an M8Cube with a 3 kW milling spindle during aluminium milling

| Component | Energy consumption |

|---|---|

| Milling spindle | 1.3 kWh |

| Cooling unit | 1.1 kWh |

| Other consumers | 0.3 kWh |

| Total | 2.7 kWh |

Innovative Technology Made in Germany

In close collaboration with universities and selected technology partner companies, DATRON is involved in numerous research projects aimed at bringing about innovative, more efficient production processes. Our innovativeness is demonstrated by numerous patents, and DATRON has been awarded the TOP100 seal of quality as one of the most innovative midsized companies in Germany.

Saving Energy:

Very low consumption despite high milling volumes thanks to the use of energy-efficient technologies.

Saving Resources:

Minimum-quantity cooling lubrication systemfrom 30 ml/hour. Very low cleaning outlay required.

Saving Space:

large working area with an extremely small footprint.

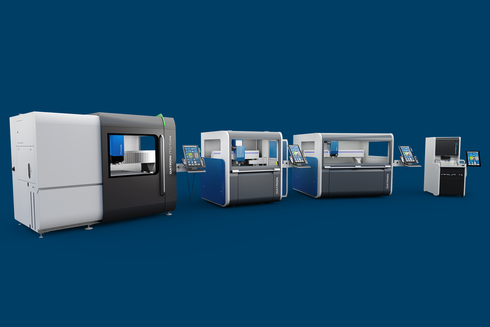

Get a look at our milling machines

The key benefits to you are state-of-the-art machining technology, high quality and efficiency.