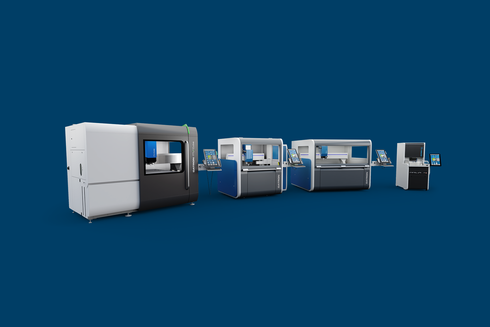

CNC Milling Machines, Dispensing Systems, Tools and Customer Care - Everything from one Source

We see ourselves as a solution provider for industrial milling and dosing. All our products are modular and coordinated with each other. This enables us to provide you with the best possible support for your day-to-day challenges in operational practice. Your productivity is what drives us. In everything we do.

High-Speed Milling and Dispensing

If you want to efficiently machine aluminium and other NEM materials using HSC technology or are looking for a high-precision solution for dispensing different media, you will find it in DATRON's CNC machine portfolio.

Milling Tools

Thanks to state-of-the-art production technologies in our own tool grinding shop and the know-how of our DATRON tool experts, we manufacture quickly, flexibly and with a focus on highest precision.

Customer Care

The economic success of our customers is based on efficient production processes, well-trained machine operators and reliable production solutions, machines and tools. Our Customer Care Team looks after you in all matters after the machine purchase. In doing so, we strive for a long-term relationship with you as a customer and are happy to go the "extra mile" for you.

DATRON Online Shop

Discover our wide range of milling tools and accessories!

24/7/365 we are available to B2B customers with our wide range of milling tools and accessories. Order today and get your DATRON milling tools - developed, designed, ground in Germany and tested all over the world - delivered to your company at short notice.

We will be happy to advise you personally!

There are many reasons to work at DATRON

Welcome to the DATRON Team!

Our employees play a vital role. As a medium-sized company, DATRON has received a number of awards for its innovative strength and corporate success. DATRON is one of the 100 most innovative enterprises in Germany. This success would not have been possible without our great staff. That is why DATRON attaches special importance to them! Their know-how, friendliness towards customers, ability to integrate in our teams, and their contribution to our success are the qualities we appreciate at DATRON. But see for yourself! If you are interested in one of our job advertisements, please send us your application. We will be happy to get in touch with you!

Your DATRON contact

Please feel free to contact us at any time!

If you have any questions or would like to know more about our products, please do not hesitate to contact us. We are happy to help!