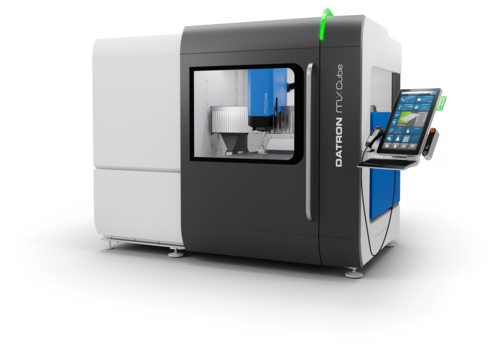

MXCube Interior

Look around & get excited

Use your mouse or the arrows below the image to see the full range of the DATRON MXCube interior. With a click on the blue circle you can get further information.

Highlights

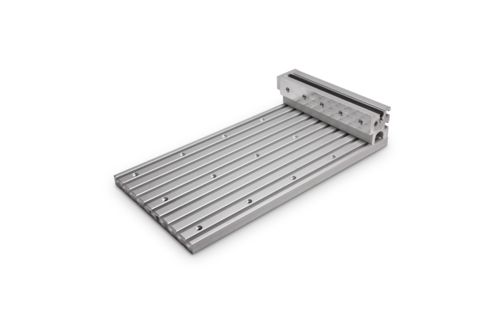

Automation & handling are part of the basic requirements

- Heavy plates or clamping systems can easily be brought into the work area manually or by crane. Integrate an individual automation solution for a process-safe series cycle!

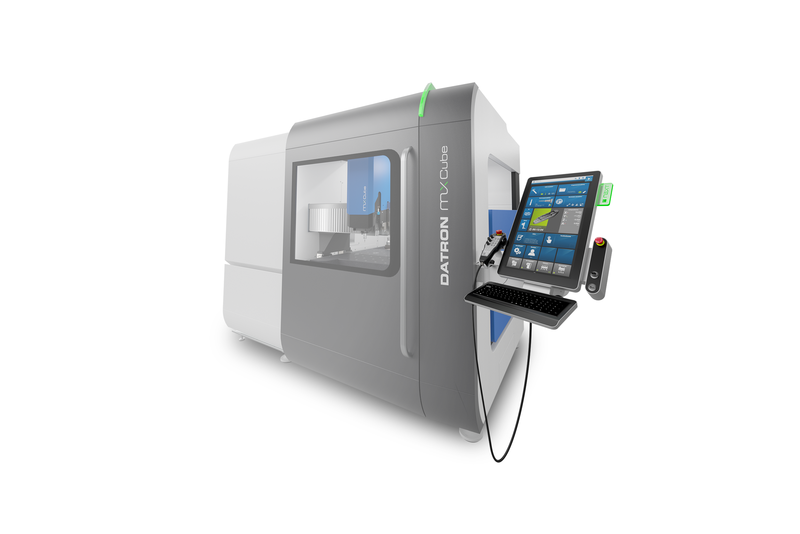

Ergonomics and overview are important

- The rugged steel construction in groundbreaking design was made for years of industrial use. Excellent accessibility to all functional elements simplifies operation and maintenance. A large window provides the best view of the machining operation, while the machine status can be seen from a distance thanks to the sharp LED display.

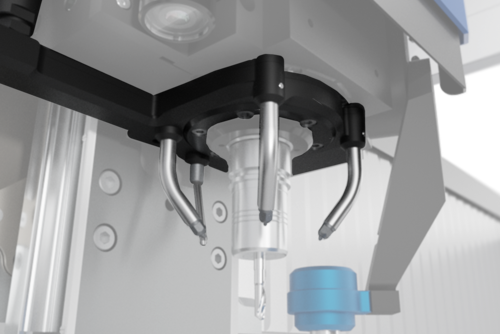

Optimum conditions for HSC milling are a must

- Great dynamics, high speeds and feeds, a rigid portal structure, and the resource-saving minimum quantity cooling lubrication enable you to achieve optimum results when machining for example aluminum and non-ferrous metals.

Saving resources also means saving precious space

- The DATRON plus: An extraordinarily large work area in relation to the compact footprint.

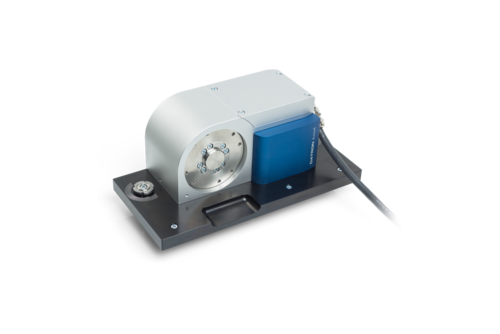

Only available from us:

- The (r)evolutionary DATRON machine control makes HSC milling easy, process-safe and comfortable. Even machine operators without years of milling experience can quickly achieve excellent machining results. more »

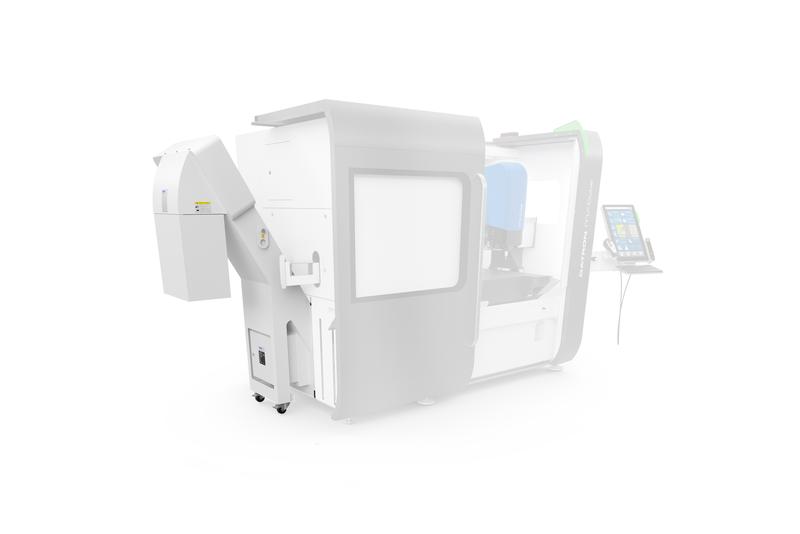

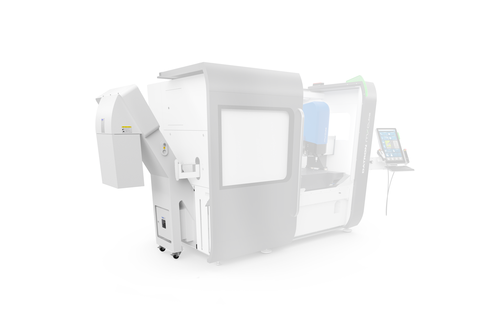

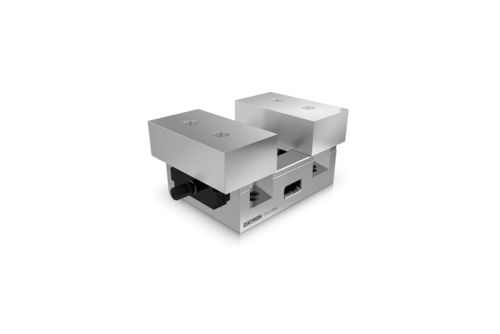

DATRON

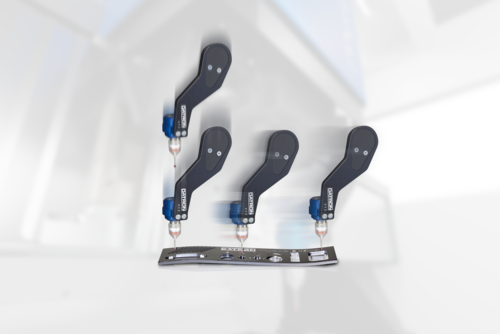

Automation

By connecting an automation solution, heavy plates, workpieces or clamping systems can be brought into the workspace of the DATRON MXCube by robot or crane. The MXCube can be loaded from optional positions through optional automation ports.