Ease of use – Milling has never been easier!

Ease of use – Milling has never been easier!

- Intuitive DATRON next control

Easy set-up – Good for small spaces

- Plug&Play principle

- Small footprint

- Fits through a standard door

Impressive productivity

- High acceleration

- Integrated 3D measuring probe

- 24 tool slots

- Compact design

- Integrated spraying system

User-friendly in all areas

- Integrated monitoring sensors

- Clear overview during the milling process

- High precision

- High surface quality

- Ergonomic design

Moderate configuration effort

- Tailored equipment

DATRON neo Variants

DATRON neo Accessory Packages

Be prepared and flexible with our packages for your DATRON neo and DATRON neo+. We have experience and know-how that we can share with you for your benefit!

DATRON vacuum chuck segments offer maximum clamping force and ease of use ...

To extend the possibilities with regard to multi-sided machining, round engraving ...

The pneumatic-clamping system moves with the click of a button to ensure ...

The fine dust generated when machining plastics or wood is removed efficiently ...

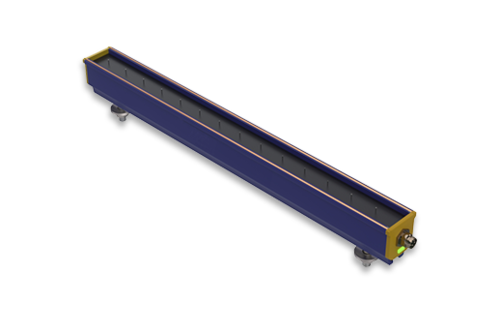

The DATRON neo Ionizing bar facilitates chip management during plastic machining ...

more information here ...

*Image similar

The DATRON neo table helps the user to organize tools and measuring equipment within easy reach.

Our DATRON neo Accessories to help you get started milling right away!

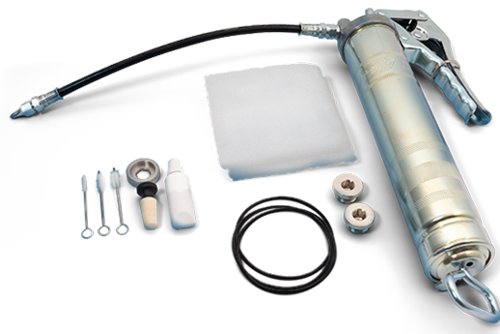

With Our DATRON neo maintenance kit we provide you the necessary products ...

DATRON neo Starter Set

Our DATRON neo Accessories to help you get started milling right away:

To use a wide variety of tools, you will also receive precisely manufactured adapters and stop rings. These allow the use of tools with different shank diameters. Also included are two ideal insertion tool.

Scope of delivery:

- 1x adapter insertion tool for 6mm and 8mm collets

- 1x insertion tool for tools with 8mm shaft diameter

- 1x adapter collets 3mm to 8mm diameter

- 1x adapter collets 1/8‘‘ to 8mm diameter

- 3x adapter collets 6mm to 8mm diameter

- 6x limit stop ring 8/12.5mm, brass

- 3x limit stop ring 8/18 mm, brass

- 1x steel

- Ruler 300 mm

DATRON neo Maintenance Set

Secure it to a permanent machine availability. With Our DATRON neo maintenance kit we provide you the necessary products for a careful preventive maintenance.

- Cleaning agents and lubricants

- Filter and seal kit

- Grease Press

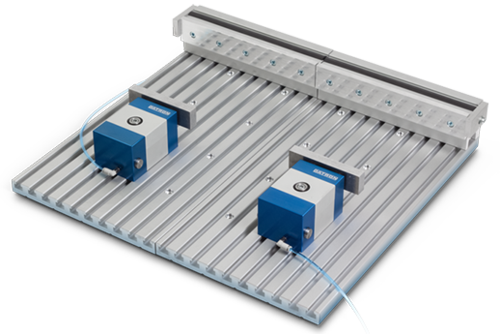

DATRON neo Vacuum Set

DATRON vacuum module clamping plates offer maximum clamping force and ease of use, achieved by the special DATRON vacuum distribution. Two vacuum plates specifically designed for DATRON neo are operated separately via connectors recessed in the worktable. Each plate is subdivided into 10 segments that - depending on component size - can be activated individually. To distribute the vacuum optimally below the workpiece, we have developed the DATRON VacuCard, a special cardboard, which serves as a sacrificial layer.

Description:

- For easy and secure clamping of sheet material

- Includes all accessories and consumables required for use of DATRON neo vacuum technology

Scope of delivery:

- 2x vacuum module clamping plate 500mm x 200mm (includes limit stop rings and mounting material)

- 1x vacuum pump

- 50x VacuCard 500mm x 200mm

- 50x VacuCard 500mm x 400mm

- 1x vacuum key

- 1x double flute end mill stepped with edge radius (for facing vacuum module clamping plates)

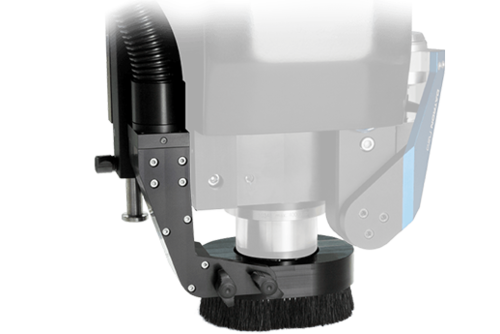

DATRON neo Dust Extraction System

The fine dust generated when machining plastics or wood is removed efficiently with the optional DATRON neo dust extraction.

Description:

- Removes dust and small chips for a cleaner machining area and better quality parts

- Installation by the customer is possible

- Height adjustment within the control

- Automatic mode

- Not for use with coolant

Scope of delivery:

- Extraction system consisting of suction head with brush and lifting unit

- Vacuum with air filter

- Hoses

DATRON neo Pneumatic Clamping Set

The pneumatic-clamping system moves with the click of a button to ensure quick job setup and changeover. According to your needs, you can use it on a T-slot plate or in stationary manner.

Description:

- T-nut plate for flexible clamping capability

- Short-stroke clamping element for quick and secure clamping of work pieces with one hand

Scope of delivery:

- 1x T-nut clamping plate right

- 1x T-nut clamping plate left

- 2x short stroke clamping element KSE-PH

- 1x dove tail milling tool

DATRON neo Keyboard Kit

Scope of delivery:

- 1x USB keyboard black (dust- and waterproof according to IP 68)

- 1x metal holder

- 4x screws for mounting on display holder

- cable tie

DATRON neo Depot Cover Hood

Description:

This upgrade package for the DATRON neo provides an additional level of process reliability and ease of operation.

The cover for the tool magazine minimizes the penetration of chips into the tool magazine, thus reducing the time needed to clean the tool holders. The risk of unintentional loosening of workpieces during machining is reduced by monitoring the applied vacuum.

By monitoring the level in the coolant tank, the risk of increased tool wear or breakage due to lack of coolant is reduced.

Scope of delivery:

- Cover for the tool magazine

- Sensor and control functions for vacuum monitoring

- Sensor and control functions for level monitoring of the cooling lubricant tank

- Mounting material

- USB stick with activation key file

Hint:

This upgrade is only available for the DATRON neo Series 2 machine generation.

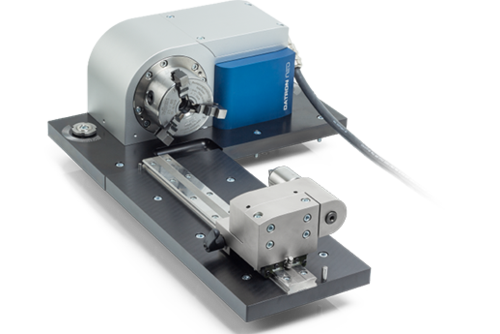

DATRON Axis4

Description:

- To extend the possibilities with regard to multi-sided machining, round engraving

- Positioned on the left side of the machine table

- A module clamping plate with centring cone and a recessed grip enables fast and precise positioning on the machine table

- Easy to retrofit

Technical specifications:

- Center height: max. 55 mm (different when using the optional accessories)

- Plug&Play capability

- Mounting: Flat surface with D=106 mm nd centric fit (34h6)

- Drive: 200 Watt AC-Servo with toothed belt, multi-turn absolute encoder

- Modulo-360° operation

- Resolution: < 0,0001°

- Maximum speed: 60 1/min

- Dimensions (X x Y x Z): 109 mm x 244 mm x 145 mm

Scope of delivery:

- Rotary axis on module clamping plate

- Rotary axis control

- License 4th axis for DATRON next control unit

Optional accessories:

The optional accessories for the rotary axis will be arranged according to your requirements

- Axis4 tailstock

- Axis4 three-jaw chuck

- Axis4 centric clamps

DATRON neo table

The DATRON neo table helps the user to organize tools and measuring equipment within easy reach.

Description:

- Table for Datron neo for storing tools and measuring equipment, light anodised.

- Vibration decoupled from the machine with rubber buffers

- Storage field for measuring equipment, channel for pen, storage places for tools with d=10.5mm stop ring

- Holder for adapter insertion tool for 6+8 mm collets 0068337D (not included in delivery)

- Holder for insertion tool stop ring 8 mm shank tools 0068180A (not included in delivery)

- Holder for the vacuum locks in the table and the corresponding 10 mm Allen key (not included in delivery)

- Hook for compressed air gun

DATRON neo Ionizing Bar

The DATRON neo Ionizing bar facilitates chip management during plastic machining. The ionization bar discharges the adhering chips inside the machine, allowing them to fall into the chip box through compressed air. This significantly reduces cleaning efforts throughout the process.

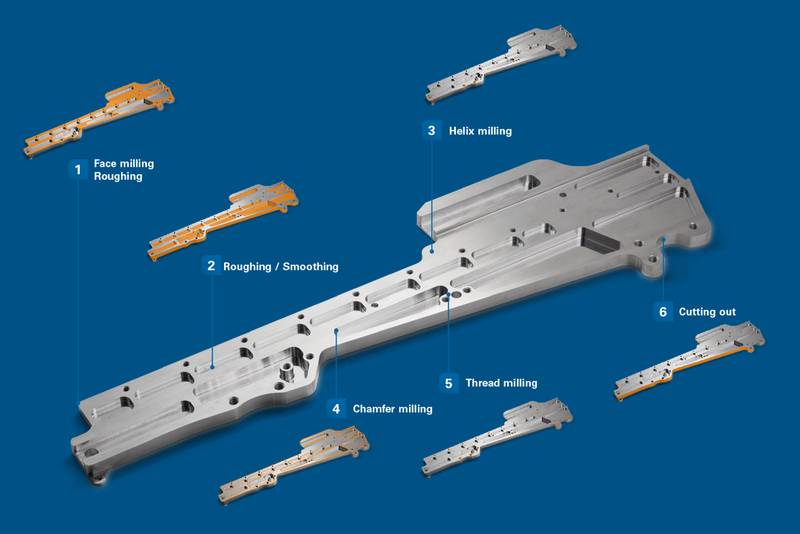

Areas of application / industries

Prototype and mold making

Companies can use the DATRON neo flexibly for molds and prototypes

"Prototypes are one of the major challenges in everyday milling. The versatility of the DATRON neo is proven by its ability to handle a variety of materials with high-quality results."

Small businesses and craftsmen

Smaller companies and craftsmen who produce specific parts in

small quantities or prototypes.

“Good ideas don‘t always transform into real parts overnight, but with DATRON neo they‘re here in a fraction of the time.“

Engraving industry

With the DATRON neo, the specific requirements such as surface quality, accuracy, small components and individual production can be met.

“DATRON neo produces mirror-like edge finishes and detailed engraving … even on rounded surfaces!“

Aerospace industry

In this industry, the DATRON neo can be used for the production of precision parts in airplanes, spacecraft, drones and other components.

DATRON provides Industrial milling solutions for the Aerospace industry that set technological, qualitative and economically-sustainable standards for production.

Consumer goods industry

Production of plastic parts for various consumer goods, from functional items (wallets) to decorative items (acrylic pictures), the DATRON neo is ideal for processing plastic.

Rout curved and planar surfaces of acrylic and outer contours with mirror polished edge finish and achieve optimal results by the combination of coordinated milling cycle with DATRON neo and DATRON milling tools.

Additional sectors that have overlaps with the sectors already described are:

- Research and development departments

- Educational institutions

- Electronics industry

- Medical technology

- Automotive industry

- Metal processing companies