- Execution of a programme starting from a label

- Compressed air status display (not for DATRON neo)

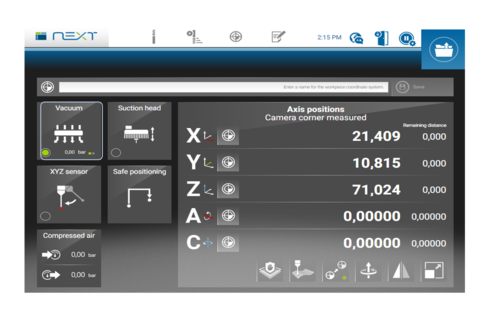

- Vacuum status display (not for DATRON neo)

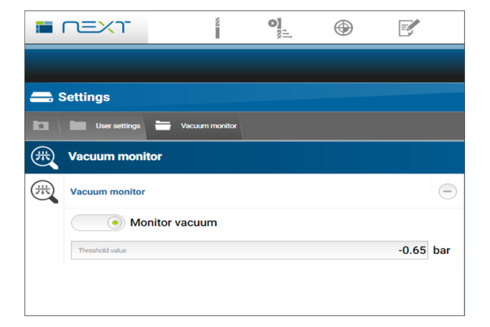

- Vacuum monitoring function (not for DATRON neo)

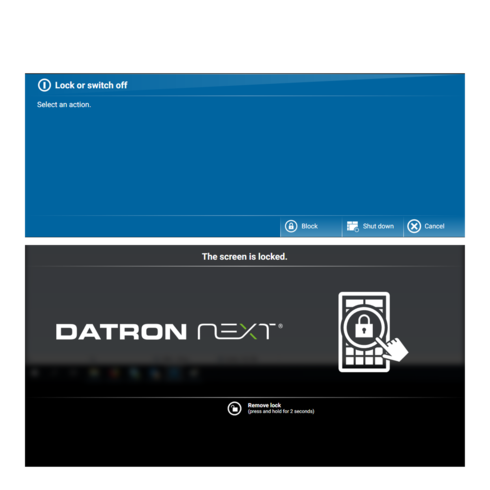

- Screen lock

- Graphical simulation icons in the 3D view

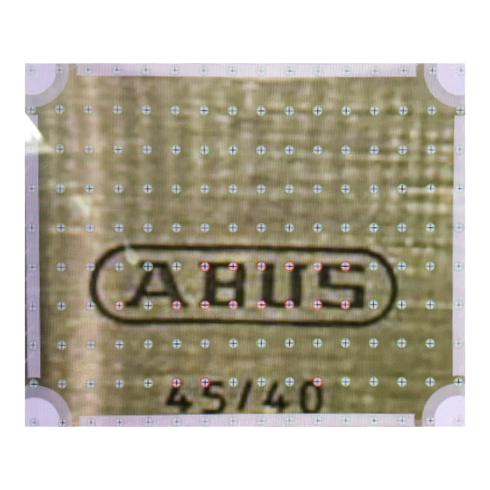

- Surface profile/Z measuring field - Exclude measuring points

- Surface profile/Z measuring field - Better representation of the extrapolation range

- New SimPL command “Sleep”

- Extension of the SimPL command “Spindle” with the parameter “Directions”

- Extension of the SimPL command library with Math commands

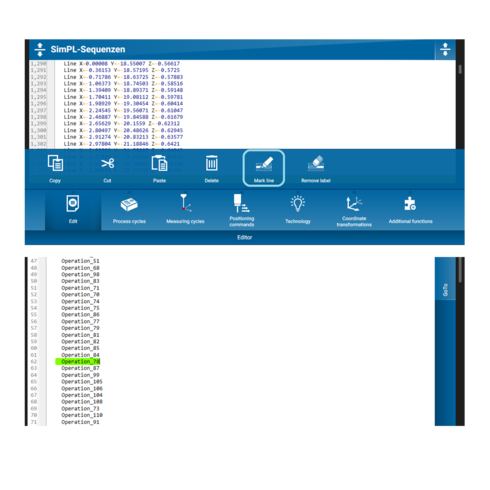

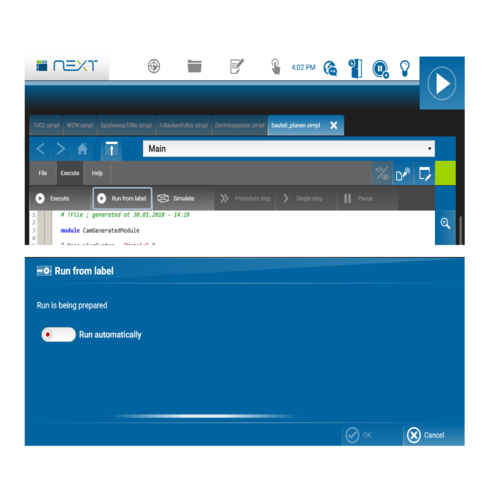

Execution of a programme starting from a label

To increase the flexibility in executing programmes, it is now possible to start a milling process in the editor from any desired programme line. To do this, proceed as follows:

- Place the cursor at the desired programme line in the editor.

- Select the option “Zeile markieren” (Mark line). The line will be highlighted in green.

- In the “Execute” menu, choose “Run from a label”

- Programme execution is then prepared and a corresponding dialogue, which must be acknowledged at the end with “OK” to start execution, is displayed.

The preparation may take a while, depending on the size of the programme. If you do not want to wait, you can start the programme directly after the end of the calculation by activating the option “Run automatically”.

Note: If the mark is within a programmed loop, an additional dialogue to define the number of runs will be displayed.

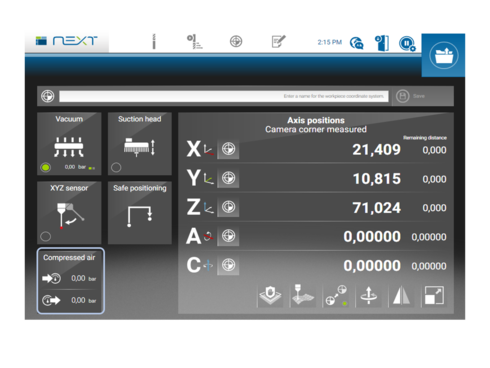

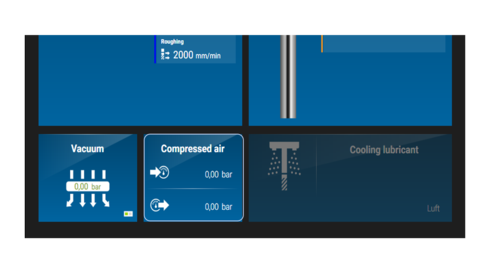

Compressed air status display (not for DATRON neo)

The compressed air status can now be displayed on M8Cube, MLCube and M10Pro machines with the DATRON next control system. Display elements are located in the section “Work piece setup and “Runscreen”. The control element for pressure displays the value of Pin (input pressure) and Pout (output pressure).

Please Note: To activate the functions to display the status of compressed air and vacuum, as well as for vacuum monitoring, changes to your machine configuration to be performed by DATRON Service are required. Please contact service@datron.de so that the necessary settings can be made. Please note that this requires access to your machine using Teamviewer.

Vacuum status display (not for DATRON neo)

The vacuum status can now be displayed on M8Cube, MLCube and M10Pro machines with the DATRON next control system. The prerequisite is that the machine is equipped with a vacuum distributor with appropriate sensor technology. A corresponding control element showing the vacuum value is then displayed in the sections “Work piece setup” and “Runscreen”.

- Hint: The element displaying vacuum is provided with a green progress bar similar to the spindle speed, allowing you a better follow-up of how vacuum develops within programme execution.

- Please Note: To activate the functions to display the status of compressed air and vacuum, as well as for vacuum monitoring, changes to your machine configuration to be performed by DATRON Service are required. Please contact service@datron.de so that the necessary settings can be made. Please note that this requires access to your machine using Teamviewer.

Vacuum monitoring function (not for DATRON neo)

There is now a function for vacuum monitoring to increase milling process reliability. If it is activated, the milling programme is paused as soon as the vacuum value falls below a threshold value. The operator then has the option of cancelling or resuming programme execution.

- Note: The threshold value is pre-set to -0.65 bar. Please note that this value does not offer any guarantee concerning blank displacement on the machine table during machining. For this reason, we recommend adjusting the value to your individual requirements

- Please Note: To activate the functions to display the status of compressed air and vacuum, as well as for vacuum monitoring, changes to your machine configuration to be performed by DATRON Service are required. Please contact service@datron.de so that the necessary settings can be made. Please note that this requires access to your machine using Teamviewer.

Screen lock

It is now possible to protect the screen of DATRON next with a lock function against undesired operation. To activate the lock, press the “next” symbol (top left) for 3 seconds and select the option “Block” in the subsequent dialogue.

Note: To unlock the screen, hold the touch screen anywhere for 2 seconds.

Graphical simulation icons in the 3D view

The icons in the 3D view have been redesigned to have a more similar look to the design in your machine.

Surface profile/Z measuring field - Exclude measuring points

Individual measuring points can be excluded from measurement in the Z measuring field of a surface profile, If you do not want to measure at some point (for example above a hole), you can deselect the measuring point by tapping it. The deselected measuring point will then be displayed in red.

Note: The outer contour must always be measured completely. No points can be deselected there.

Surface profile/Z measuring field - Better representation of the extrapolation range

The extrapolation range of the Z measuring field is now displayed more transparently in order to better recognise the underlying workpiece contour.

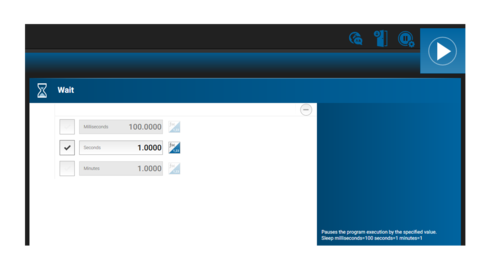

New SimPL command “Sleep”

As of now, you can use the “Sleep” command in a SimPL programme. The command can be added directly to the programme via text input or via the corresponding input dialogue.

The command is used to pause the execution of a programme for a desired period of time. As soon as the code line with the “Sleep” command is reached, the programme execution pauses for the specified duration.

Command

Sleep minutes=1

seconds=1

milliseconds=100 Parameter “minutes” (optional): Number of minutes to pause the execution of the programme.

Description

Parameter “seconds” (optional): Number of seconds to pause the execution of the programme.

Parameter “milliseconds” (optional): Number of milliseconds to pause the execution of the programme.

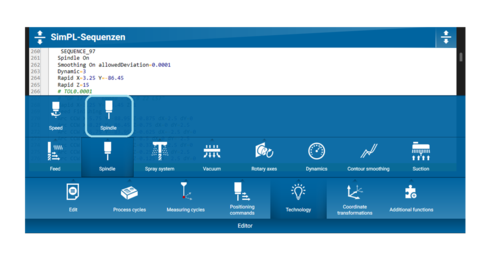

Extension of the SimPL command “Spindle” with the parameter “Directions”

The command “Spindle” has been extended with the parameter “Directions”. This allows to determine the direction of rotation of the spindle. The new parameter can be added directly to a programme via text input or via the corresponding input dialogue.

Command

Spindle mode=On direction=CW

Description

New parameter “direction” (optional). The values available are “CW” (ClockWise) and “CCW” (CounterClockWise).

Note: The use of this command requires a spindle with right/left rotation.

Extension of the SimPL command library with Math commands

As of version 2.3, the function scope of the programming language SimPL has been extended with the addition of Math commands. This allows to perform calculations in milling programmes. The new commands can be added directly to a programme via text input. Please note that there are no symbols for the Math commands in the menu at the bottom of the screen yet.

Functional Description

| Command | Description |

|---|---|

| X = Sin(4) | Stores the sine of angle 4 (radians) in the variable X. |

| Y = Cos(-2) | Stores the cosine of angle -2 (radians) in the variable Y. |

| Z = Tan(1.5) | Stores the tangent of angle 1.5 (radians) in the variable Z. |

| X = Asin(0.3) | Stores the arc sine (angle in radians) of the value 0.3 in the variable X. |

| Y = Acos(0.1) | Stores the arc cosine (angle in radians) of the value 0.1 in the variable Y. |

| Z = Atan(0.5) | Stores the arc tangent (angle in radians) of the value 0.5 in the variable Z. |

| X = Sinh(4) | Stores the hyperbolic sine of the value 4 in the variable X. |

| Y = Cosh(2) | Stores the hyperbolic cosine of the value 2 in the variable Y. |

| Z = Tanh(1.5) | Stores the hyperbolic tangent of the value 1.5 in the variable Z. |

| S = Sqr(3) | Stores the square of 3 (i.e. 9) in the variable S. |

| S = Sqrt(26) | Stores the square root of 25 (i.e. 5) in the variable S. |

| X = Log10(100) | Stores the common (decimal) logarithm of 100 (i.e. 2) in the variable X. |

| X = Log(10.5) | Stores the natural logarithm of 10.5 in the variable X. |

| euler = Exp(1) | Stores the value of the exponential function (ex) for x = 1 (i.e. the Euler number) in the variable euler. |

| R = Round(2.6) | Stores the value rounded to the nearest integer of 2.6 (i.e. 3) in the variable R. |

| R = RoundDecimals(1.27456,2) | Stores the value rounded to 2 decimal places of 1.23756 (i.e. 1.24) in the variable R. |

| S = Sign(-3) | Stores the value -1 in the variable S. Sign returns -1, 0 or +1 depending on the sign of the argument. |

| F = Floor(-2.4) | Stores the value -3 in the variable F. Floor returns the next adjacent integer less than or equal to the argument. |

| C = Ceiling(4.9) | Stores the value 5 in the variable C. Ceiling returns the next adjacent integer that is greater than or equal to the argument. |

| p = Pi | Stores the circle number p in the variable p. Pi is a programme (without parameters), not a function! This means that a line which contains only Pi is a valid SimPL order. However, it has no effect. |

| euler = E | Stores the Euler number e in the variable Euler. Euler is a programme, not a function! This means that a line which contains only E is a valid SimPL order. However, it has no effect. |

| m = Max (3, 4) | Stores the maximum of 3 and 4 (i.e. 4) in the variable m. |

| m = Min (3, 4) | Stores the minimum of 3 and 4 (i.e. 3) in the variable m. |

| Z = Atan2(0.5, -0.5) | Stores the arc tangent (angle in radians) of the quotient 0.3/-0.5 in the variable Z. |

| Z = Power(2, 10) | Stores the result of 210 (1024) in the variable Z. |

| R = Radian(180) | Converts the angle 180° to radians and (thus the value p) and stores the result in the variable R. |

| D = Degree(2) | Converts the angle 2 in radians to degrees and stores the result in the variable D. |

Note: Calling up functions has a different syntax than calling up programmes: The parameters must always be enclosed in parentheses and the names of the parameters are not specified. As a result, such calls are easily nestable. The return value of a function must always be used, i.e. it is either assigned to a variable, used as a parameter to call up a function or programme, or used in a mathematical expression. Generally, using an invalid argument (e.g., log (-1)) will trigger a runtime error. In trigonometric functions, angles are expected and returned in radians.