Your benefits at a glance:

- Extremely large working area requiring little floor space.

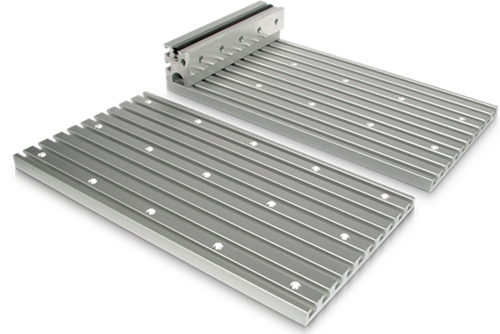

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments.

- Available with table cutout for vertical clamping technology, appropriate for machining high components (optional).

- Contour smoothing package PerfectCut for fast, accurate and contour faithful HSC milling with excellent surface quality: your machine is more powerful and stays “fit” longer, even in cases of high- volume production (optional).

- New chip carriage design with allocation to multiple containers (stackable) to promote work ergonomics.

Applications

Electronics

- Front panels and housings

- Membrane keyboards

- Test adapter drilling

- Drilling and milling of test devices

- Milling of solder frames

- PCB milling

- Plastic sheet processing

- Composites

- GRP/CRP materials

Aerospace

- Machining of aluminium plates

- Machining of aluminium profiles

Advertising industry and exhibition stand construction

- Processing of signs

- Processing of profiles

Printing

- Hot stamping dies

- Stamping tools

Automotive supply

- Precision CNC machining

Medical

DATRON machine software

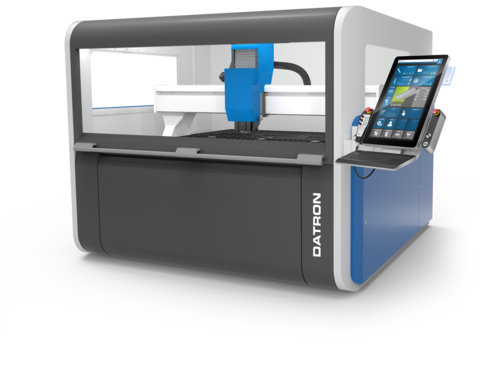

A special highlight is the completely new developed (r)evolutionary DATRON next machine control. Some special features are smartphone-like operation via a 24" touch screen, automatic tool management, camera-assisted setup of zero points, very dynamic control for fast machining and perfect surfaces.

CAM Software

The "DATRON next" control works with generated milling programs of the standard interface DIN/ISO. In order to be able to use the full range of functions of the next control, however, we recommend an individually created postprocessor.

Please ask your CAM manufacturer for this. Our experts from the application technology department will be happy to support you in creating and optimizing the postprocessor.

DATRON

MLCube LS

great large format and highly precise

Your benefits at a glance:

- Extremely large working area requiring little floor space.

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments.

- Available with table cutout for vertical clamping technology, appropriate for machining high components (optional).

- Contour smoothing package PerfectCut for fast, accurate and contour faithful HSC milling with excellent surface quality: your machine is more powerful and stays “fit” longer, even in cases of high-volume production (optional).

- New chip carriage design with allocation to multiple containers (stackable) to promote work ergonomics.

Highlights

- High dynamics through optimized control and mechanical construction designed for acceleration and rigidity

- Highly precise milling even with dynamic temperature drifts

- Very high cutting performance using the smallest tools due to the high-speed precision high-frequency spindles with up to 60,000 rpm and outputs from 0.6 to 4.0 kW

- Rigid, low-vibration machine construction optimized for excellent surface finishes when using FEM for machining

- High precision due to its high-quality linear guides, ball screw spindles, HSK-E 25 tool insert (optional) and precisely-crafted structural elements

- Continuously repeatable and precise milling results