3- and 5-axis milling machines for post-processing additively manufactured components

What does hybrid post-processing mean?

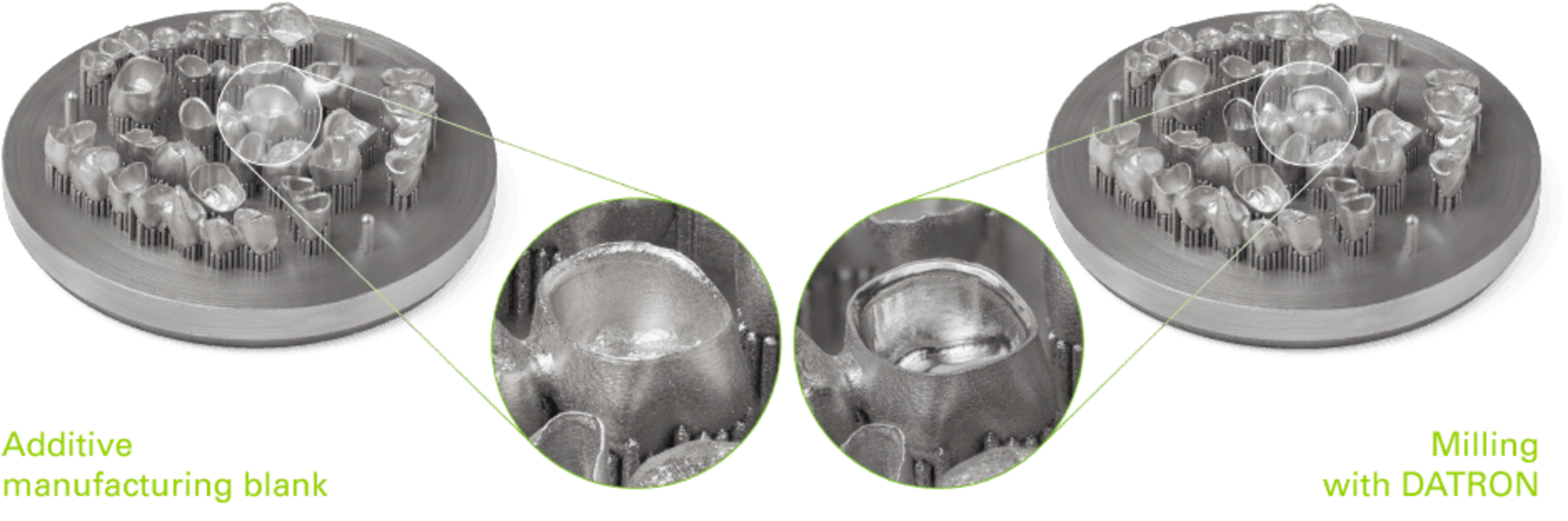

Due to the technical processes used, dental indications additively manufactured of cobalt-chromium or titanium often come with a high surface roughness and so-called holding pins (supports). Especially in the dental field, where it is of utmost importance to achieve a perfect fit and a tight seal of crown margins, implant connections or occlusal surfaces, these parts are subjected to post-processing with the aid of high-precision milling machines. Thus, a combination of additive (laser sintering) and subtractive (milling) manufacturing takes place and opens up completely new production possibilities and business models.

What does DATRON provide for the hybrid process?

In general, it can be said that each additively produced component can be subjected to post-pro- cessing. DATRON supports you in this process from the idea to the implementation with especially adapted machine systems and a comprehensive range of accessories, such as measuring technology, milling tools and appropriate software solutions plus consulting - tailored to your individual needs and requirements!