- Fitting Assistant

- Editor 2.0

- PDF in DATRON next

- Improvements in measuring “Insert Command” (for all DATRON machines fitted with a camera)

- Surface profile improvements (for all customers with the purchase option “Surface Profile”)

- DATRON Live Remote Link App

- Other Improvements

Fitting Assistant

€ - PURCHASE OPTION | NO additional hardware required

For all customers who want to get the most out of their machine and manufacture items that have to fit precisely, the new “Fitting” option is now available.

The geometry is created with a defined allowance and then measured using the XYZ measuring sensor. With the deviation that has now been determined, end mill, machine and process tolerances can be compensated in a second step.

A typical example are holes with a tolerance of H7.

Please note: This functionality is a purchase option.

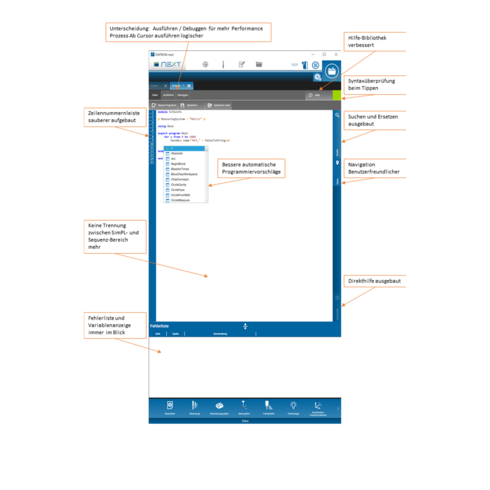

Editor 2.0

Starting with version 2.14, DATRON next comes with a new Editor.

For all those who work a lot with CAM programmes, there is now only one view (regardless of whether you are working with the main part or the sequence). As of now there are no longer any restrictions for searching / replacing in sequences.

In addition, code completion (automatic completion when writing) is now also available with SimPL and provides a performance boost when writing SimPL commands. Auto-completion (code completion) now runs in the background in the editor, which significantly simplifies the writing of SimPL commands. In addition, the code is checked for errors in real time. Previously, it was always necessary to save first to do this.

In the current release, programming errors are recognized immediately and not only after saving.

The debugger can be an advantage when looking for errors in the process; it now also works across files. With the new DATRON next release, you can also jump to library programmes during the process.

Simply install the new editor: it is freely available.

- Differentiation between execution and debugging for even higher performance

- Starting with “Execute Cursor”, the process is even more transparent

- Clearer structure of the line number bar

- The separation between SimPL and the sequence area has been removed

- Error list and variable display at a glance

- Expanded help library

- Syntax check directly while typing

- Expanded “Search and Replace” functionality

- Even more friendly navigation

- Expanded direct help

PDF in DATRON next

Do you have drawings with tolerances which have to be checked? Or have you saved instructions for setting up components?

DATRON next can now also open PDF files. This means that production plans, technical drawings or setup instructions can be opened directly on the machine.

Download the update 2.14 for DATRON next now and get your machine updated to the current standard.

Improvements in measuring “Insert Command” (for all DATRON machines fitted with a camera)

Tip for DATRON customers with camera option:

Insertion of camera modules

After a complex surface profile has been set up with the camera, this measuring cycle (including all parameters) can now be transferred directly to the code as if it were a module. This is particularly advantageous if individual measuring points have been deleted.

It is now possible to insert a measurement command previously executed with the camera into the programme so that it is automatically called up for all other components.

Surface profile improvements (for all customers with the purchase option “Surface Profile”) Oberflächenprofil It is now possible to deactivate measuring points at the external edges of the surface profile. This way, you can now process irregularly shaped

It is now possible to deactivate measuring points at the external edges of the surface profile. This way, you can now process irregularly shaped workpieces using a surface profile more easily than previously.

We suggest you also try the combination with “Insert command”.

When setting up the surface profile with the camera, simply deactivate the measuring points that you do not need, measure the workpiece again and insert them into the programme. This way, even complex tasks can be carried out easily.

Function Description

- When setting up a Z measuring field in the camera image, individual measuring points can be deactivated by tapping them. This allows you to omit individual measurements on holes in the component, for example. Until now, it was not possible to deactivate measuring points that were on the edge of the measurement rectangle. With DATRON next release Version 2.14, all measuring points, including edge points, can now be deactivated.

This also allows measuring non-rectangular components, such as U- or L-shaped components. - The SimPL command “SurfaceCompensationZGridMeasure” now displays the measuring points as simple position lists. Each position in this list corresponds to the position of a probed point on the surface of the workpiece in the workpiece coordinate system.

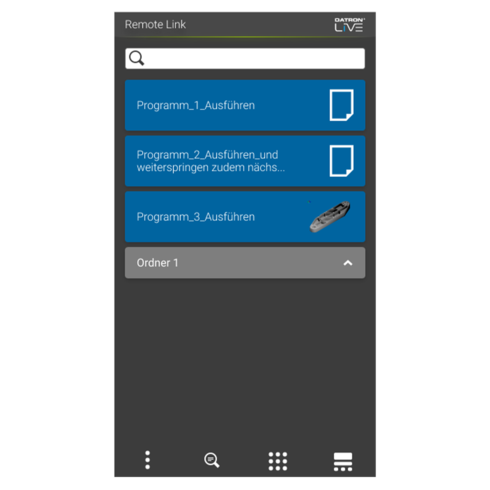

DATRON Live Remote Link App

The DATRON Live Remote Link App, SimPL allows programmes to be executed via DATRON Live. The programmes are SimPL macros which, for example, switch off the vacuum or shut down the machine.

Requirement

DATRON next 2.14 or higher.

To use the DATRON Live Remote Link app, you have to activate item 0A01389D via a license key. Further licenses, e.g. for the DATRON Live Dashboard are not necessary.

Procedure

- Activate the license key

- Grant DATRON Live app users the right to use the DATRON Live Remote Link app

- Navigate to Settings -> User Settings -> DATRON Live

- As usual, create a user and grant the corresponding authorization.

- Add programmes to the DATRON Live Remote Link app

- To add a program to the DATORN Live Remote Link app, open the programme management. Select the programme and add it using the action buttons at the bottom of the screen.

- All added programs are located in the special folder “Remote link” in the “Machine” section.

- Log in to DATRON Live and select the Remote Link app via the app overview

- Running a programme

Tap the programme you want to run or swipe to the left. Only then will the execute button become visible. Press the button and the displayed dialogue: The purpose of this apparent chicane is the safety of the machine. This ensures that no program is executed accidentally.

All DATRON Live apps are available optionally and can be purchased at any time and activated with a license key.

For further information about DATRON Remote Link App.

Run External Programmes (For Everyone)

Do you want to decide how to continue during the execution of a programme? Do you want to enter the programme name via a dialogue or the barcode scanner?

You can now call up external programmes from SimPL while the programme is running. This also applies to exported programmes and their parameters. Proceed as follows:

Code Sample:

RunExternalProgram modulePath=“Beispiel1.simpl” programName=“ Beispiel2”

Do Not Switch off the Spindle During Panel Milling (For Customers With the “Multiple Execution” Option)

The spindle remains switched on.

Previously, when jumping from one component to the next, the spindle was switched off every time, since the “Spindle Off” command was read and executed every time.

As of DATRON next 2.14, this command is ignored and the spindle remains active in the multi-path version.

To be able to run the spindle with different components during panel milling, keep the spindle switched on.

When milling precise geometries, a number of factors can influence the result. The most important influencing variables are end mill, speed, feed, concentricity, material, sharpness, path smoothing, etc.

The entire milling process must be considered to achieve an accurate fit. The new purchase option “Fitting” helps you to implement fits as required.

Deviations from the defined allowance are detected using the XYZ measuring sensor on the machine, after the geometry has been created with an allowance in the first step. The deviations now determined help to determine the final dimension in the second step.

Summary:

- The entire process chain is taken into account.

- There is no need to remove the component from the machine, and it can be processed further with a single clamping.

- No additional equipment is required.

- The expected accuracy is directly dependent on the machine and the tool used.

- The automatic cleaning of the geometry is not always successful, which is why the “Fitting” function requires manual intervention when determining the correction values. This value can then be used later in the automatic process.

- The measurement takes place only when the DATRON standard cycles (“DrillMilling”, “Circle Cavity”, “CircleFromMid”, “RectCavity”, “RectFromMid”) are used.

After calibration, the correction values can also be saved in the tool radius, to be also available for operations and contours using radius compensation.