- The Autopause dialog is now called execution options

- Adjustable parameters for the pneumatic cleaning of the tool magazine

- New function for simple engraving of text

- Setting up the tool changer by the operator

- More comfortable workflow in the editor throught link to existing dialog windows

- Filter in the Tool Management Dialog

- New default value for the lowest Z-height in the Z-measurement field dialog box

- New standard behavior of the surface profile when activated via milling programme

- Filter in the Tool Management now also considers tool number

- New sample files available in DATRON next

- New Dialog for programming the measuring field available in the editor

- Execute programs directly from the HomeScreen

The Autopause dialog is now called execution options

The “Automatic pauses” and “Restart from abort” functions can now be found in the new “Execution options” dialog. This can be reached via the new icon attached to the execute button at the top right of the HomeScreen.

The Execution Options dialog has been redesigned to be a permanently visible dialog with help texts and most importantly more space for future enhancements / so stay tuned 🙂

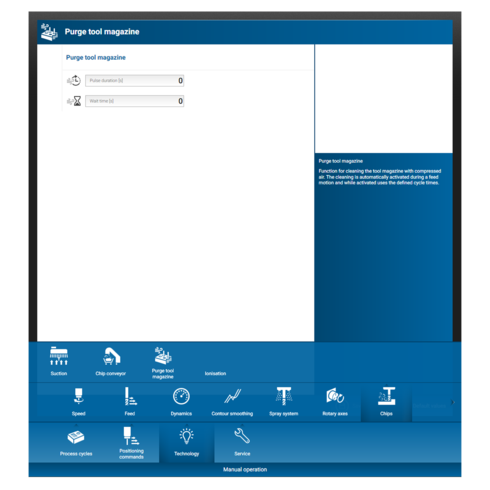

Adjustable parameters for the pneumatic cleaning of the tool magazine

In order to make chip removal in the tool magazine even better, the pulse and waiting times can be set individually as of now. This means that the blow-out cycles can be adapted much better to the respective type of machining.

Attention: This function only has an effect in combination with the 12-way changer with cover.

New function for simple engraving of text

A new engraving function is now available for performing easy marking tasks, such as engraving a number or a label on a workpiece.

A label can be created either via the dialogs in the manual operation or via a function call in a SimPL program.

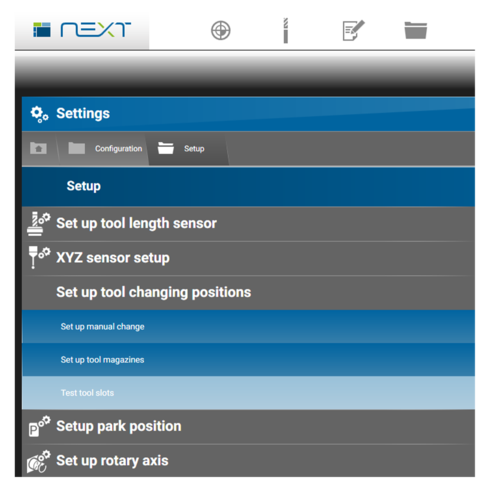

Setting up the tool changer by the operator

With Release 2.8, you as a customer can use the functions for setting up the tool magazine and the manual change position yourself. This is necessary, for example, if a tool pot is worn out or damaged and has to be replaced. In future, it will no longer be necessary to call in a service technician on site.

Attention:

Please note that a measuring adapter is required to calibrate XYZ. After replacing one or more POM tool holders, the tool locations must be checked and the replaced POM tool holders need to be set up. The following requirements must be met in order to do so:

- At least version V2.8 of the machine control system must be connected to the must be installed on the machine.

- The XYZ sensor is calibrated and the offset between the tool tip and probe tip are calibrated.

- You have a measuring adapter if you use collets of the type use HSK-E 25.

- If you use collets type HSK-E 32, the following is sufficient an empty collet chuck.

- The affected tool magazines are empty.

More comfortable workflow in the editor throught link to existing dialog windows

When using input masks in the Editor to create milling programs, existing dialogs from other areas can now also be used. For example, when programming tool changes. This is helpful to avoid having to switch between the dialogs in the editor and the other areas.

This new feature is available for the following tasks:

- Adding Workpiece Coordinate Systems to a Milling Program

- Programming of tool changes

- Adding User Modules

So far the process has looked like this:

When programming a tool change via the input masks, the user must currently jump to the tool administration, search for the tool there, remember the number and jump back to the editor again and enter the number there. As of version 2.8, the tool manager can be opened directly during programming to search for the tool and insert it into the milling program.

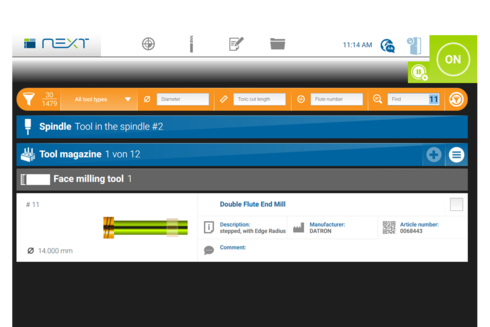

Filter in the Tool Management Dialog

You can access tool management in various ways. For example, if you tap on the illustrated spindle in the Manual operation area. Up to now, the filter function was missing if you used the tool management path described. It is now available.

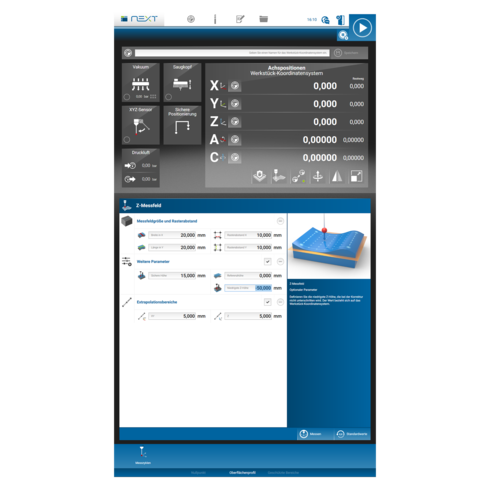

New default value for the lowest Z-height in the Z-measurement field dialog box

The default value of the lowest Z-height in the measurement dialog of the Z-measurement field has been adjusted. Instead of -5 mm now -50 mm are set.

This value describes the lowest Z-height that is not fallen below when milling with the Z-measurement field switched on. This parameter is a safety function with which the height correction in Z is limited. You can use it, for example, to prevent the correction in the extrapolation area – in which a continuation of the Z-measurement field contour is “only” calculated – from leading to machining underneath the vacuum plate.

New standard behavior of the surface profile when activated via milling programme

If the measurement of a Z-measurement field has been started via a SimPL program, the resulting Z-measurement field is automatically saved with immediate effect. Previously, it was automatically discarded in favor of a Z-measuring field which might have been set up manually.

Now, thanks to the “Resume after abort” function, the production of an incomplete workpiece can be continued – including the surface correction by the associated Z-measuring field, even if the z-measurement field had been set up via a milling programme.

Filter in the Tool Management now also considers tool number

The filter function in the tool management has been extended. From now on it is also possible to filter according to the unique tool number.

This number is assigned by the controller when a tool is used and is only available once on the machine.

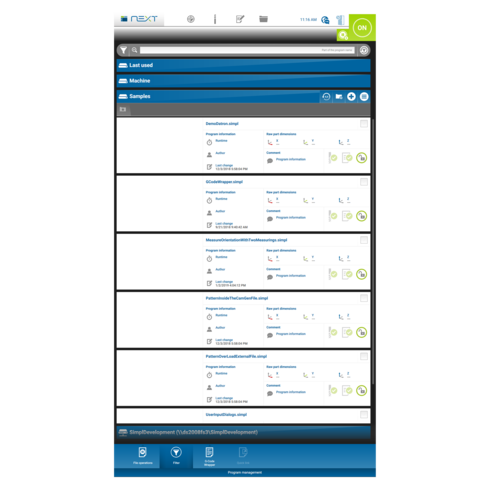

New sample files available in DATRON next

New examples are now available in the Samples folder of the program management:

DemoDatron.simpl

Serves in general to explain the structure and functionality of a SimPL program. This file is referenced in another program (PatternOverLoadExternalFile.simpl).

GCodeWrapper.simpl

Used for the translation and execution of GCode programs in the next controller.

PatternInsideTheCamGenFile.simpl + PatternOverLoadExternalFile.simpl

To illustrate the Pattern command, which can be used to execute a part at different positions in a grid.

UserInputDialogs.simple

To explain how to create input dialogs that must be filled in by the machine operator during program execution.

New Dialog for programming the measuring field available in the editor

If you want to add the measurement cycle “Z-measurement field” to a SimPL program, you can now do so in a comfortable way via an input mask in the editor. Until now, the programmer had to insert the relatively long command “manually” into the program.

Execute programs directly from the HomeScreen

Programs that are to be executed frequently can now be created as shortcuts on the HomeScreen. Select a program via checkbox in the program administration and add it to the Shortcuts. The program link is then displayed with its own icon on the Home Screen and can be started directly.

This function is helpful, for example, if you want to start or stop an accessory that is connected to the machine via the individual I/O modules – e.g. an automatic door, a suction unit or similar.