- New cycle in editor: "Blow free workpiece".

- Query of tool data in a SimPL program (e.g. GetTool...)

- Display of third file formats in program management

- New function in the graphic tool magazine to remove several tools or move them to the warehouse

- New SimPL command for activating a spindle warm up in the milling program (SpindleWarmup)

- Formatting of input dialogs (in SimPL programs) using Markdown

- New possibility to customize the user interface - tile 'extraction' only show if an extraction is also connected

- 3D Simulation: Status information on points in the 3D simulation

- New example file for handling the String functions

- Filter in WT Check (Assignment)

- Display the zero point of the simulation better (Home Screen and Run Screen)

- Sister tool management: Tool breakage detection

- Surface profile: New function for managing several Z-measurement fields

- New input masks in the editor for easy programming of commands around the Z-measurement field

- Camera feature: crosshair measurement for setup with very flat blanks

- Camera feature: Display of the bounding box in the camera image

New cycle in editor: "Blow free workpiece"

A new cycle is available in the editor with which the workpiece can be blown free.

The cycle is below: “Technology > Chips > Blow free workpiece”.

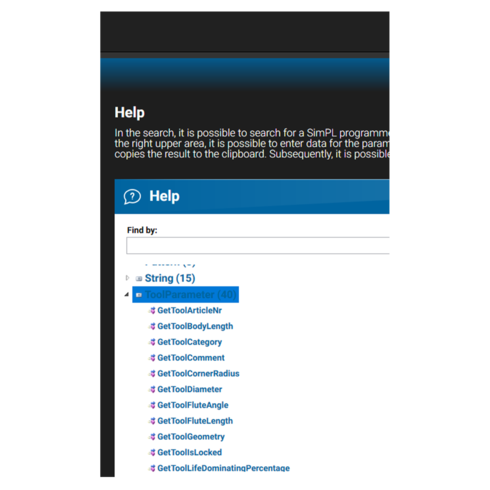

Query of tool data in a SimPL program (e.g. GetTool...)

The functional scope of SimPL has been extended by commands with which the properties of tools can be queried. This could be interesting, for example, if you want to write the lifetimes of all tools in a text file.

The available commands can be found in the Help under ToolInformation.

Display of third file formats in program management

In the program administration, foreign file formats such as text files can now also be displayed. This is helpful if a milling program is to read or write values from a text file.

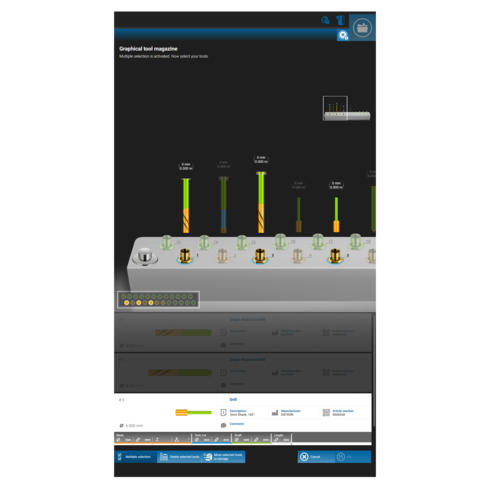

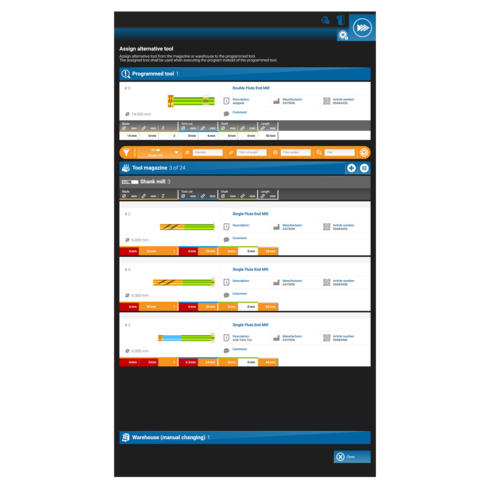

New function in the graphic tool magazine to remove several tools or move them to the warehouse

The graphic tool magazine now also supports the fast removal of tools from the machine. Multiple tools can now be selected simultaneously and then deleted or moved to the warehouse.

New SimPL command for activating a spindle warm up in the milling program (SpindleWarmup)

In order to force a spindle warm up, for example before executing a program, the SimPL library has been extended by a suitable command.

Command: SpindleWarmup forceExecution=true

The editor also contains an input dialog for this purpose.

Formatting of input dialogs (in SimPL programs) using Markdown

Texts displayed in SimPL dialogs can now be formatted using Markdown.

Markdown is a widely used syntax that allows simple formatting directly within texts.

New possibility to customize the user interface - tile 'extraction' only show if an extraction is also connected

The tile ‘extraction’ has always been displayed on the homescreen of the DATRON next control – even if no extraction system is connected to the machine. So that this no longer leads to confusion for the user, this tile can be hidden. This is done in the User Settings > Surface Settings.

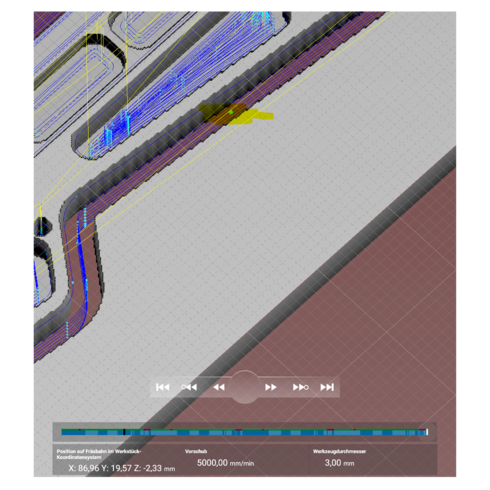

3D Simulation: Status information on points in the 3D simulation

In order to be able to better evaluate the milling program in detail, additional information is now displayed in the 3D simulation. These values are displayed initially:

Minimum position of the toolpath in the WKS

Dimensions of the milling path in the WKS

These values are displayed when marking any point on a toolpath:

- Position on toolpath

- feed

- tool diameter

New example file for handling the String functions

Under Program Management > Samples > String Modules there is a new example file that explains how to use the String commands in the SimPL programming language. Especially with the string format functions.

Filter in WT Check (Assignment)

A list of missing tools is displayed in the tool check. This list has been extended by the well-known filter function.

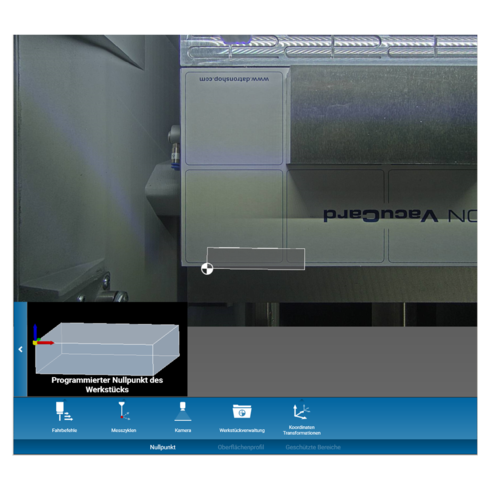

Display the zero point of the simulation better (Home Screen and Run Screen)

Sister tool management: Tool breakage detection

The sister tool management has been extended by functions for handling tool breakage. This means that program execution can now be continued with a sister tool if a tool break has been detected.

New features:

- New configuration parameters in the settings

- New options for execution after abort

- Locking of tools after detected tool breakage

Surface profile: New function for managing several Z-measurement fields

In order to be able to store and reuse the data of a measured surface profile, a measuring field management is now available. Until now, the measuring field was discarded if the machine was switched off or a new measuring field was created.

In the measuring field management a calibrated field can be stored.

The scope of the SimPL programming language has been extended to include commands for managing measurement fields.

New input masks in the editor for easy programming of commands around the Z-measurement field

The Toolbox menu of the editor has been extended by input masks around the surface profile. Input masks are available for the following functions:

- Activate/ Deactivate

- calibration

- Query existence

- Delete

- Save

- store

Camera feature: crosshair measurement for setup with very flat blanks

Some blanks cannot be touched with the 3D probe in X and Y (e.g. if they are very flat or curved). With the help of a crosshair in the camera image, such components can now be set up visually.

Note: This feature is currently still in the market testing phase. In the future we plan to offer it as an optional feature. If you are interested in a 30-day trial, please contact: service@datron.de.

Camera feature: Display of the bounding box in the camera image

To simplify setup using the camera feature, the Bounding Box of the workpiece is now displayed in the video image. The bounding box will appear after the zero point is set. It is then easier to judge, if the workpiece can be manufactured completely from the blank. Thus, errors during setup before program execution become visible. For example, if a rectangular blank was placed on the vacuum plate in the wrong direction.